How To Choose The Right Outdoor Weatherproof Enclosure

Posted: August 11, 2022 by

Jon Gelston

Tags:

Electronic Enclosures,

Quality,

Plastic vs. metal,

Waterproofing,

plastic enclosures

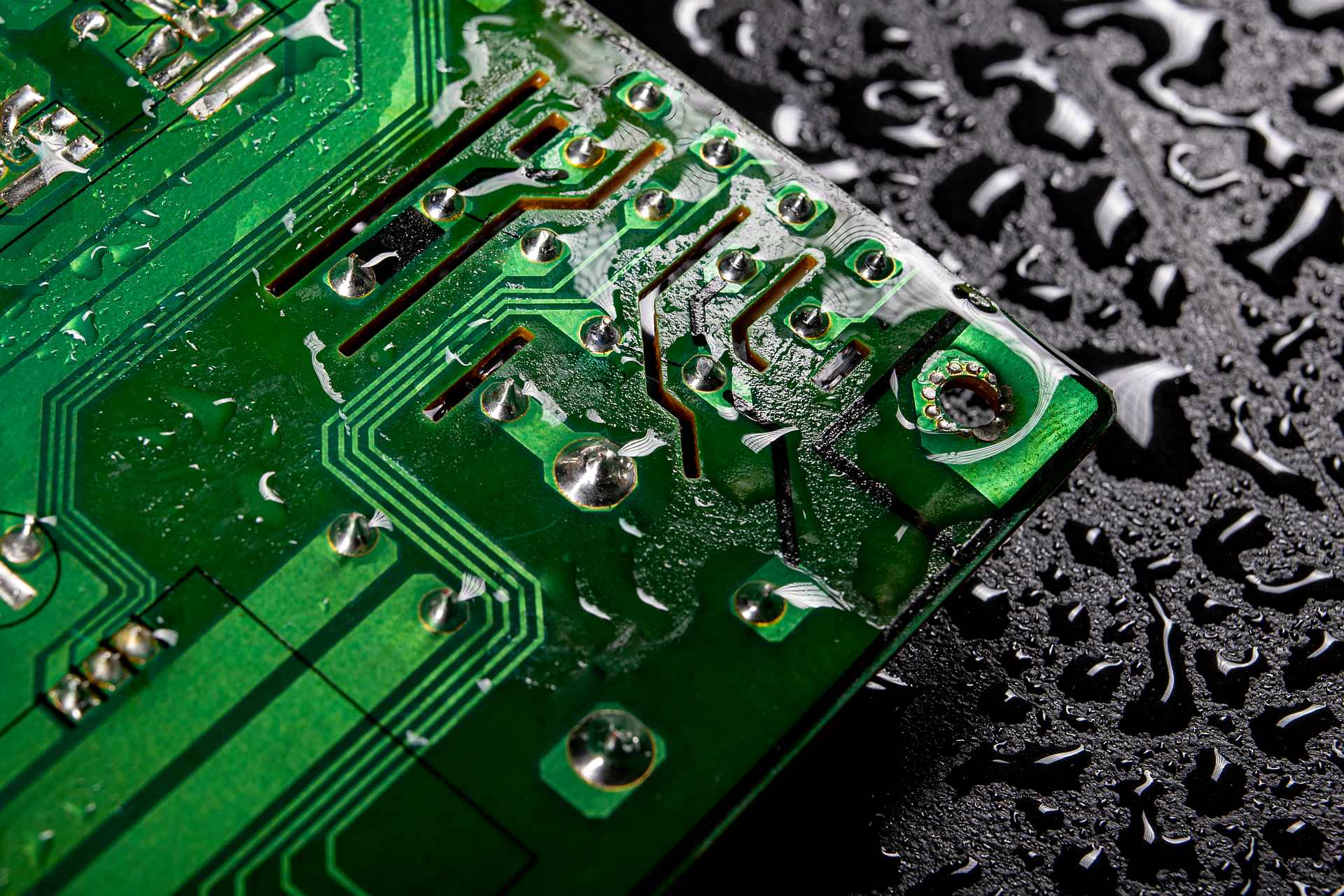

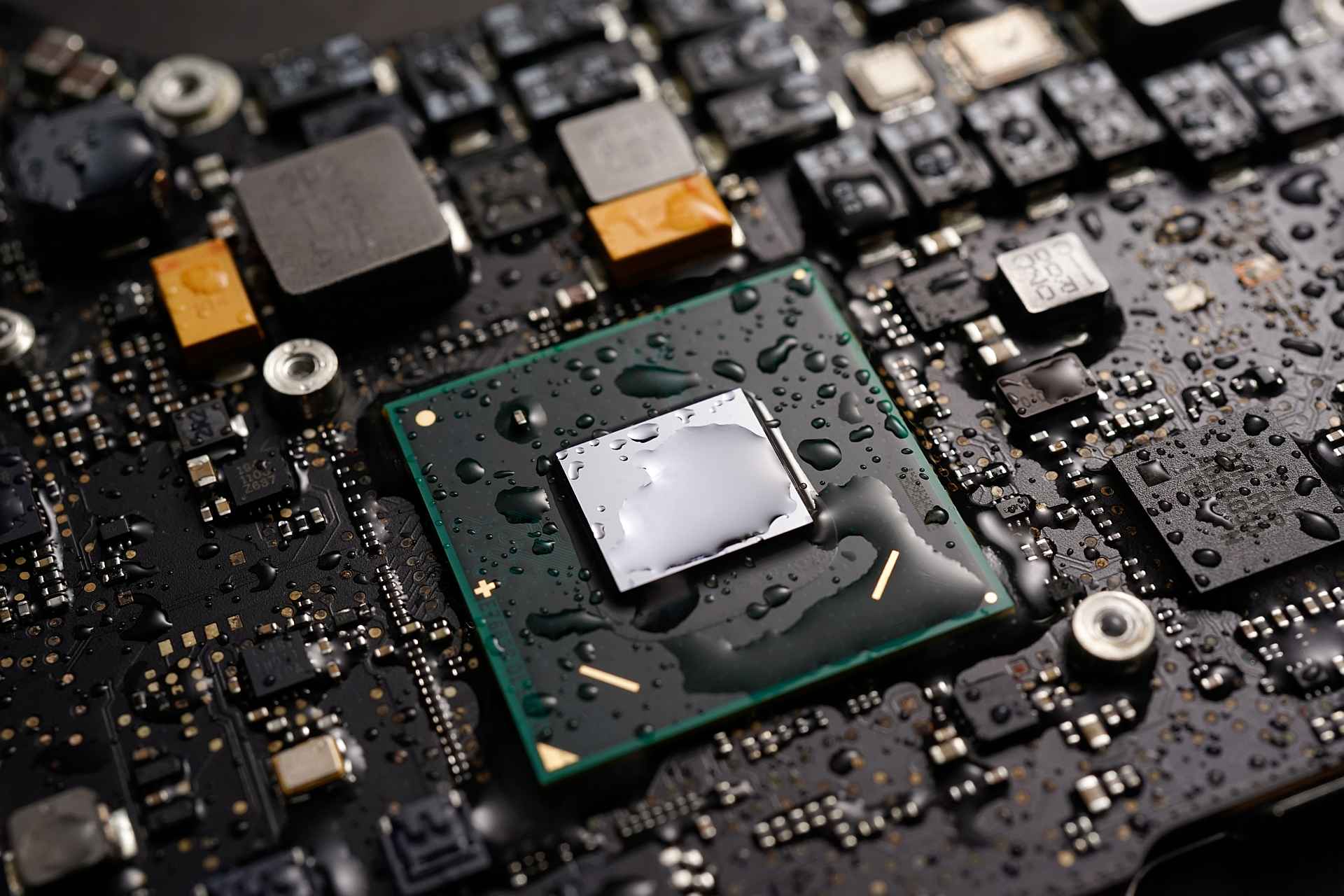

4 Tips for Waterproofing Electronic Enclosures

Posted: July 18, 2022 by

Jon Gelston

Tags:

Electronic Enclosures,

Quality,

Waterproofing

When Should You Waterproof Your Electronics Devices? Here’s An Answer.

Posted: July 5, 2022 by

Jon Gelston

Tags:

Electronic Enclosures,

Quality,

Waterproofing

Why Did That Happen? Common Problems With Threaded Inserts in Plastic

Posted: June 20, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

insert molding,

Plastic Types,

Quality,

Plastic vs. metal,

Choosing the right plastic injection molder

A Rookie's Guide to Threaded Inserts for Plastic, Injection Molding, & More

Posted: June 1, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

insert molding,

Plastic Types,

Quality,

Plastic vs. metal,

Choosing the right plastic injection molder

Simple Design Tips for Injection-Molded Parts with Complex Features

Posted: May 16, 2022 by

Jon Gelston

Tags:

Electronic Enclosures,

Quality,

Waterproofing,

Assemblies

Mistakes To Avoid When Waterproofing Electronic Devices

Posted: April 19, 2022 by

Jon Gelston

Tags:

Electronic Enclosures,

Quality,

Waterproofing,

Assemblies

4 Reasons to Add a Trusted Small Plastic Parts Shop to Your Vendor List

Posted: December 4, 2017 by

Jon Gelston

Tags:

Quality,

Choosing the right plastic injection molder

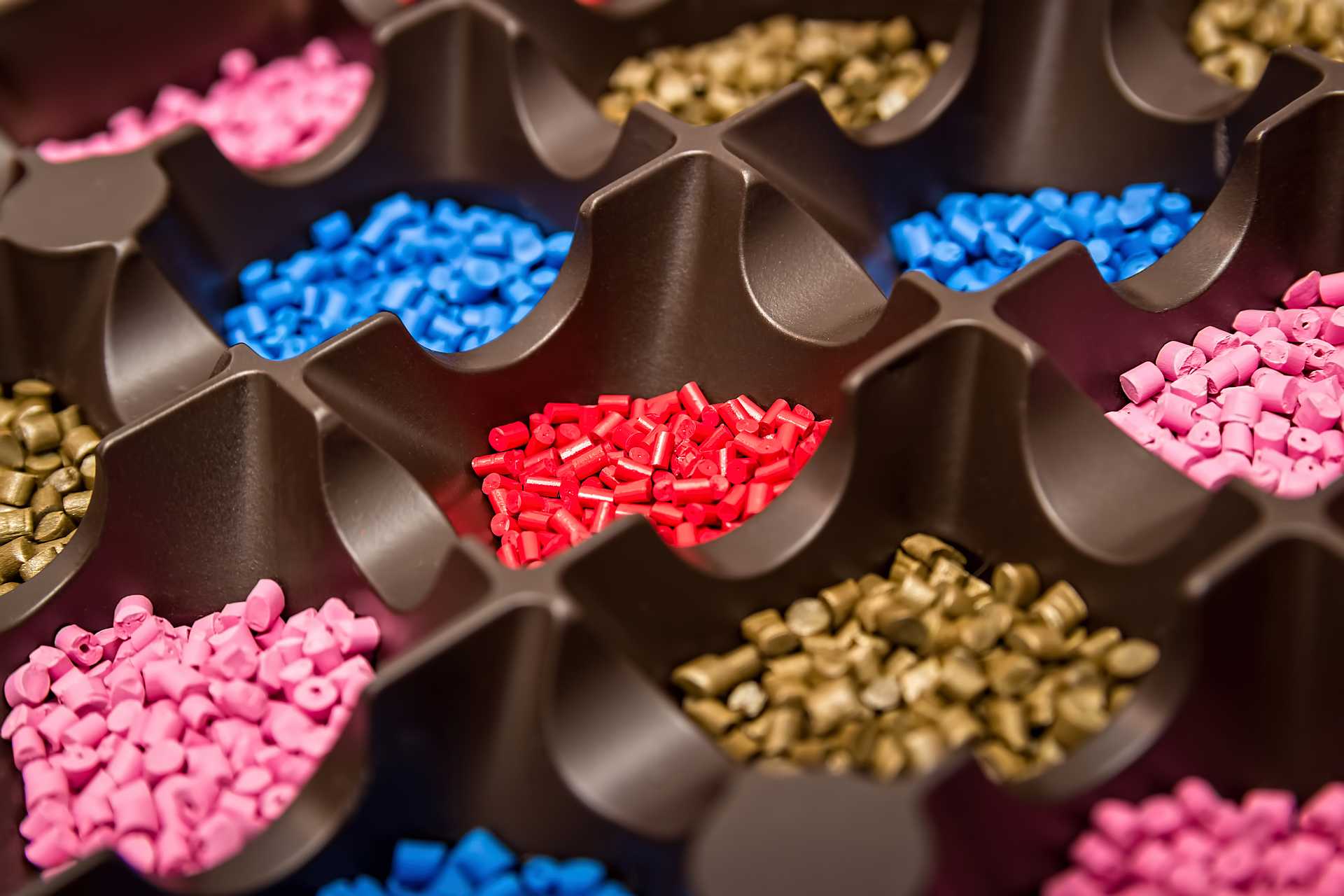

The goal of every business is continual growth. However, there are times when achieving that objective puts a strain on existing resources. That can definitely be the case with the injection molding vendor that produces the small plastic parts for your products.

A Focus on Quality that Keeps Customers Coming Back

Posted: October 24, 2016 by

Jon Gelston

Tags:

Quality

In plastic injection molding, like any business, there are many keys to success. The flexibility to meet a customer’s unique needs is important. The ability to hit deadlines by working quickly and efficiently is essential. And a focus on producing cost-effective parts is also critical. However, those characteristics (and many others) only matter if you begin with excellent quality.

SINCE 1993 MADE IN USA

SINCE 1993 MADE IN USA