Maintaining proper wall thickness is one of the most important aspects of designing custom injection molded parts. Overly thick walls not only waste material, they’re also more likely to exhibit part defects such as sink marks. On the other hand, overly thin walls are prone to warping and cracking, while also generally lacking the strength necessary for a durable end product.

How to Size Minimum Wall Thickness for Injection Molding – Optimizing Your Part Designs

Posted: August 12, 2024 by

Jon Gelston

Tags:

Electronic Enclosures,

Quality,

Plastic vs. metal,

Waterproofing,

Outdoor enclosures

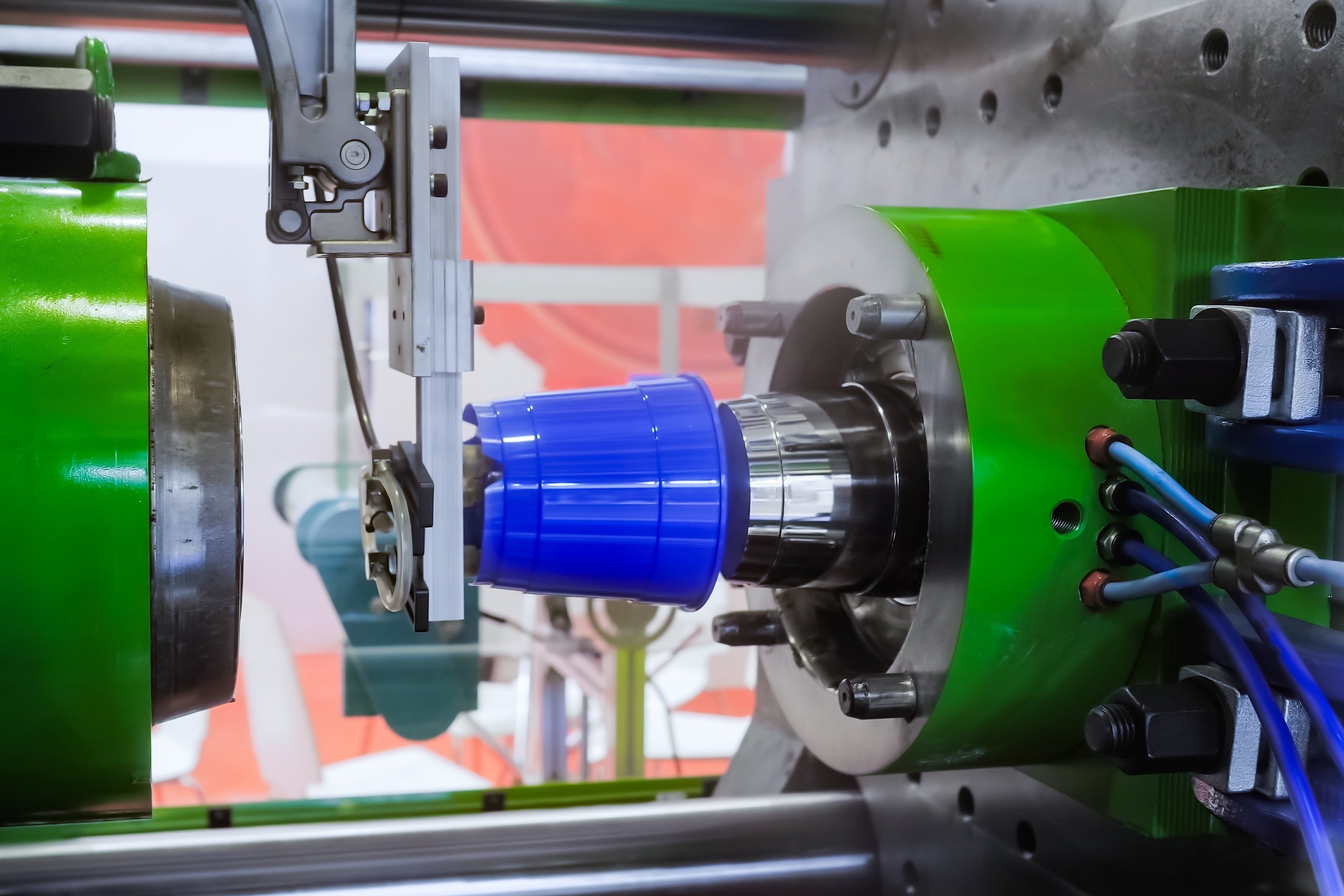

The Role of Automation in Modern Plastic Injection Molding

Posted: July 30, 2024 by

Jon Gelston

Tags:

Electronic Enclosures,

Quality,

Plastic vs. metal,

Waterproofing,

Outdoor enclosures

In the plastics manufacturing industry today, automation is the name of the game if you want to be competitive. Automated injection molding machines, robotic part handlers, automatic loading/unloading systems… In fact, automated manufacturing technology has become increasingly common throughout the American manufacturing sector as a whole. Essentially, these newer technologies help US manufacturersoperate as lean, efficient and productive as possible, thus meeting the new demands of onshoring while remaining cost competitive to the global marketplace.

Plastic Electronic Enclosures: Expectations vs. Reality

Posted: February 7, 2023 by

Jon Gelston

Tags:

Electronic Enclosures,

Quality,

Plastic vs. metal,

Waterproofing,

Outdoor enclosures

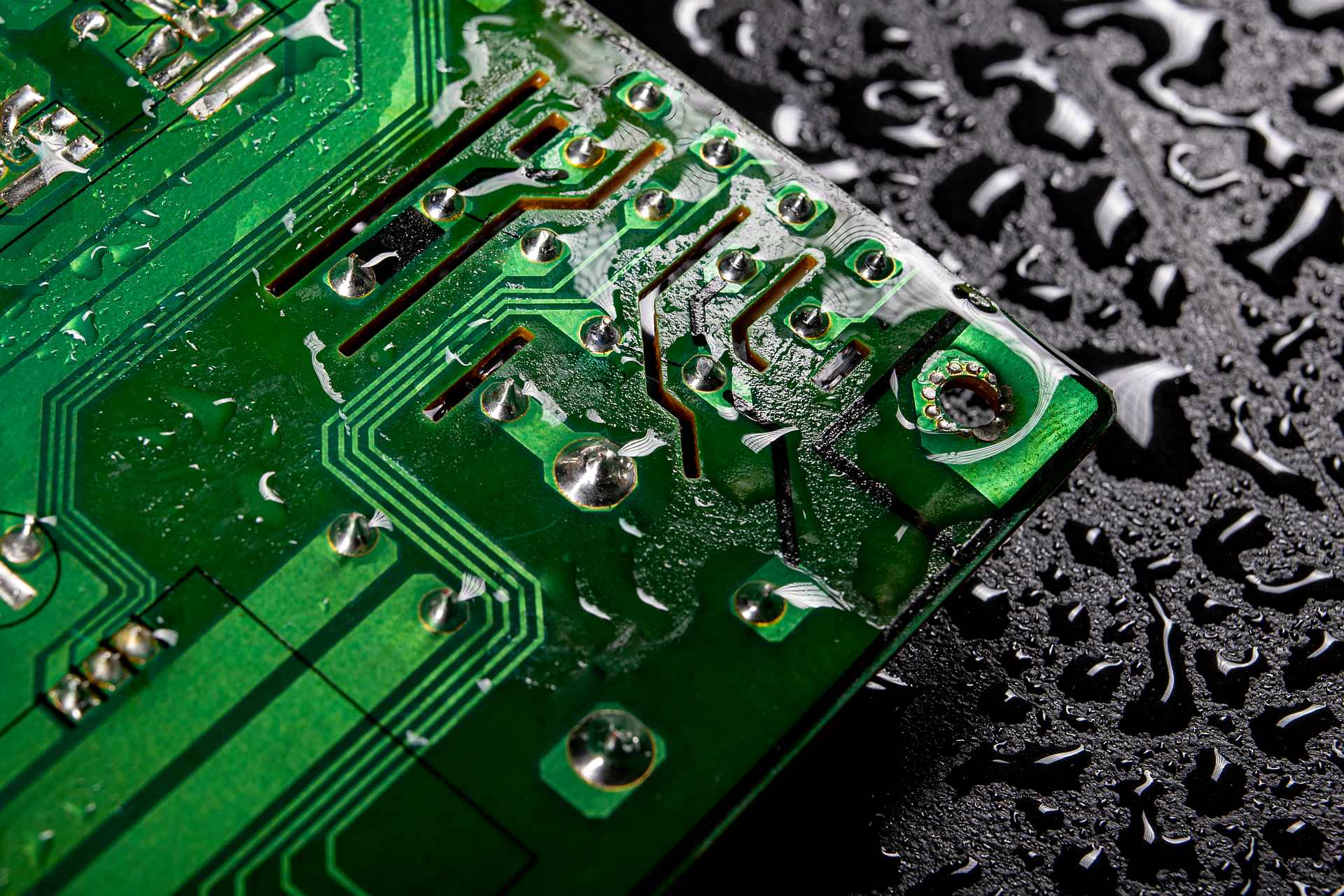

When it comes to manufacturing custom electronic enclosures, many customers have a misperception about the utilization of plastics versus metal materials. Perhaps this is because metal is the default material for so many manufacturing applications, or because plastics were traditionally inferior to metal for many products.

However, decades of engineering and innovations in materials science have substantially improved the strength, reliability, and longevity of specialized plastics. As such, custom injection molded plastics are now the preferred material for electronic enclosures in a number of unique applications.

The Most Common Uses for Plastic Electronic Enclosures

Posted: January 18, 2023 by

Jon Gelston

Tags:

Electronic Enclosures,

Quality,

Plastic vs. metal,

Waterproofing,

plastic enclosures,

Outdoor enclosures

For many applications, specialized plastics are the ideal material to use for manufacturing electrical enclosures. That’s why plastics have become the standard for a wide range of modern electronics applications. Below, we discuss some of the most common uses, along with some of the advantages of plastic electronic enclosures for these applications.

Protecting Electronics with Plastic Enclosures: Advantages and Applications

Posted: January 9, 2023 by

Jon Gelston

Tags:

Electronic Enclosures,

Quality,

Plastic vs. metal,

Waterproofing,

Outdoor enclosures

Specialized plastics are generally the ideal material used in today’s manufacturing of electronics enclosures. Compared to metal enclosures, plastic electronic enclosures offer a number of unique advantages such as enhanced durability and resistance to extreme temperatures. Additionally, production cost savings are often possible due to the efficiency of custom plastic molding design and manufacturing processes.

What to Look for in Outdoor Electrical Enclosures

Posted: December 21, 2022 by

Jon Gelston

Tags:

Electronic Enclosures,

Quality,

Plastic vs. metal,

Waterproofing,

Outdoor enclosures

Weatherproof, Waterproof, and What Else?

Custom Injection Molding: The Only Guide You Need

Posted: August 30, 2022 by

Jon Gelston

Tags:

Electronic Enclosures,

Quality,

Plastic vs. metal,

Waterproofing,

plastic enclosures

How To Choose The Right Outdoor Weatherproof Enclosure

Posted: August 11, 2022 by

Jon Gelston

Tags:

Electronic Enclosures,

Quality,

Plastic vs. metal,

Waterproofing,

plastic enclosures

4 Tips for Waterproofing Electronic Enclosures

Posted: July 18, 2022 by

Jon Gelston

Tags:

Electronic Enclosures,

Quality,

Waterproofing

SINCE 1993 MADE IN USA

SINCE 1993 MADE IN USA