As a manufacturing manager, you know the frustration: Parts arriving with inconsistent quality. Missed delivery deadlines. Phone calls and emails going unanswered. Yet despite these issues, many managers feel trapped with their current injection molding partner because they possess the tooling needed to produce critical parts.

Tooling Transfer: Breaking Free from Underperforming Injection Molders

Posted: April 14, 2025 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Injection Molding Defects,

Tool Transfer

Voice of the Customer: Empowering Medical Device Innovation Through Precision Manufacturing

Posted: October 29, 2024 by

Jon Gelston

Tags:

Plastic Injection Molding,

Quality,

Tool Transfer,

Customer

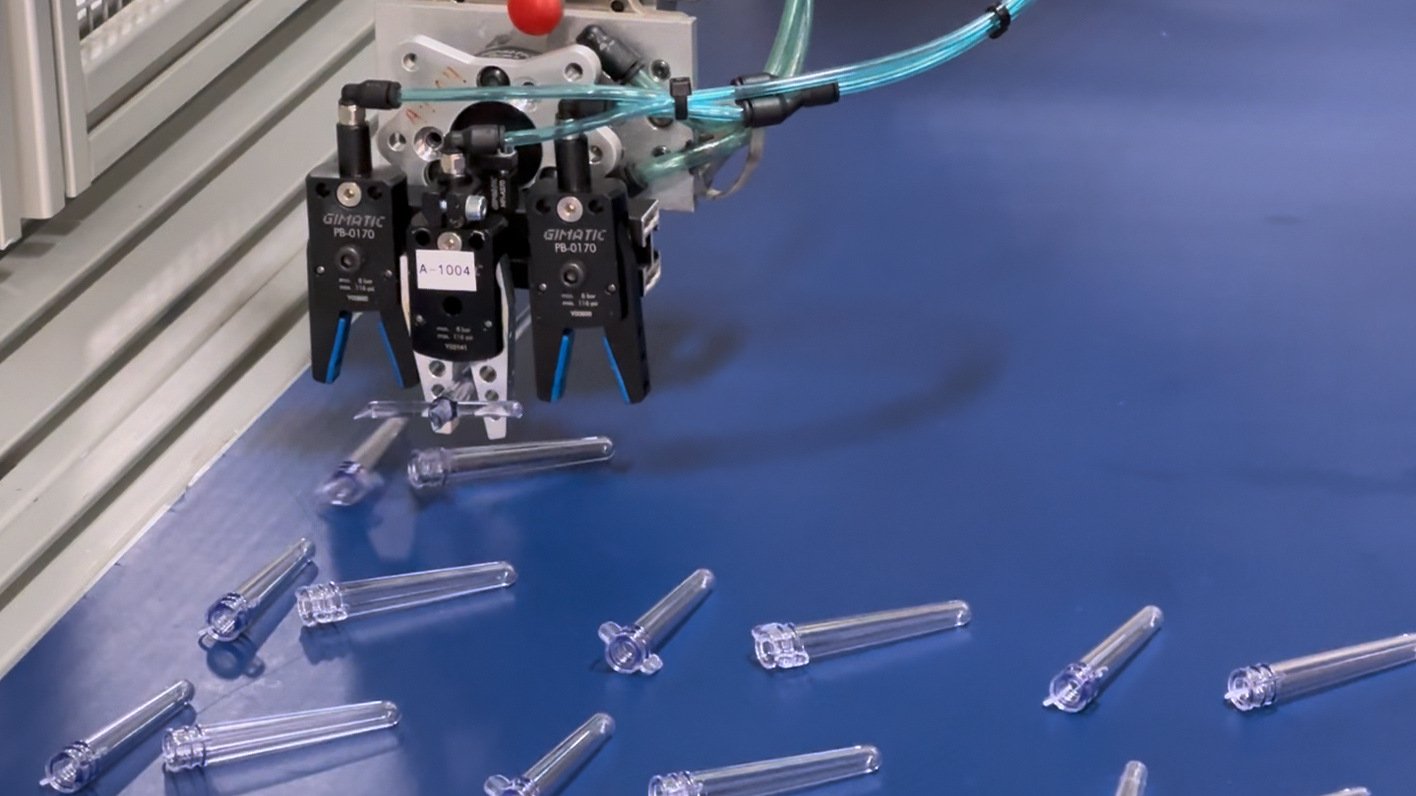

A minimally invasive medical procedure or device simplifies traditional treatment methods, causing the patient less pain and reducing the risk of complications. When Trice Medical was experiencing unnecessary complications and frustrations obtaining critical injection molded components for its manufactured equipment, it realized the need for a new business partner that could supply a reliable, painless solution. Recently, President of Trice Medical, Mike Steen, sat down to discuss his company's long-standing partnership with AIM Processing. With more than 15 years of experience in the industry, Mike shared valuable insights into the strong collaboration between the two companies, the value AIM Processing brings to the table and how their partnership has evolved over time.

SINCE 1993 MADE IN USA

SINCE 1993 MADE IN USA