For many applications, specialized plastics are the ideal material to use for manufacturing electrical enclosures. That’s why plastics have become the standard for a wide range of modern electronics applications. Below, we discuss some of the most common uses, along with some of the advantages of plastic electronic enclosures for these applications.

The Most Common Uses for Plastic Electronic Enclosures

Posted: January 18, 2023 by

Jon Gelston

Tags:

Electronic Enclosures,

Quality,

Plastic vs. metal,

Waterproofing,

plastic enclosures,

Outdoor enclosures

Protecting Electronics with Plastic Enclosures: Advantages and Applications

Posted: January 9, 2023 by

Jon Gelston

Tags:

Electronic Enclosures,

Quality,

Plastic vs. metal,

Waterproofing,

Outdoor enclosures

Specialized plastics are generally the ideal material used in today’s manufacturing of electronics enclosures. Compared to metal enclosures, plastic electronic enclosures offer a number of unique advantages such as enhanced durability and resistance to extreme temperatures. Additionally, production cost savings are often possible due to the efficiency of custom plastic molding design and manufacturing processes.

What to Look for in Outdoor Electrical Enclosures

Posted: December 21, 2022 by

Jon Gelston

Tags:

Electronic Enclosures,

Quality,

Plastic vs. metal,

Waterproofing,

Outdoor enclosures

Weatherproof, Waterproof, and What Else?

How to Select The Right Metal Inserts for Molded Plastics

Posted: November 29, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Injection Molding Tooling,

Plastic Injection Molding Defects,

Quality,

Plastic vs. metal,

Choosing the right plastic injection molder,

plastic enclosures

AIM Processing is a company that is focused on quality, and we have been dedicated to giving personalized attention to each molding project for nearly 30 years. As a result, our team takes great care to ensure that every project is constructed using the best possible materials for the intended application use. Beyond plastic, however, it can also be important to choose the proper metal inserts to work alongside the molded material. Explore some factors to consider when working with metal inserts.

Overmolding & Insert Molding: Is There a Difference?

Posted: November 15, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Injection Molding Tooling,

Plastic Injection Molding Defects,

Quality,

Choosing the right plastic injection molder,

plastic enclosures

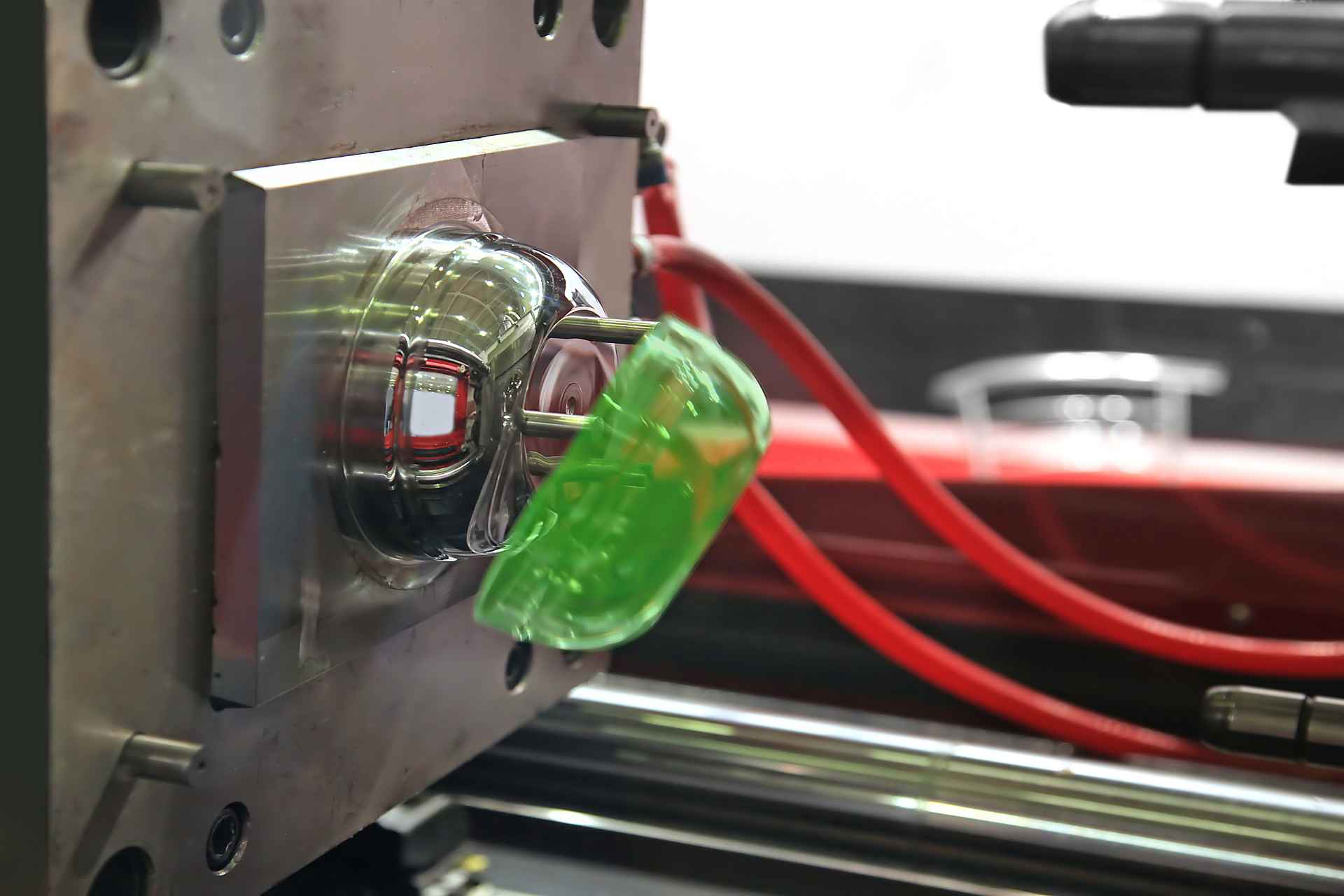

Thermoplastic Injection Mold Design for Electronic Enclosures

Posted: November 2, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Injection Molding Tooling,

Plastic Injection Molding Defects,

Quality,

Choosing the right plastic injection molder,

plastic enclosures

The Benefits of Injection Molded Parts

Posted: October 12, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Injection Molding Tooling,

Plastic Injection Molding Defects,

Quality,

Choosing the right plastic injection molder,

plastic enclosures

Plastic Injection Molding: Step by Step at AIM Processing

Posted: September 27, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Injection Molding Tooling,

Plastic Injection Molding Defects,

Quality,

Choosing the right plastic injection molder,

plastic enclosures

Most Common Injection Molding Defects and How to Prevent Them

Posted: September 14, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Injection Molding Tooling,

Plastic Injection Molding Defects,

Quality,

Choosing the right plastic injection molder,

plastic enclosures

Custom Injection Molding: The Only Guide You Need

Posted: August 30, 2022 by

Jon Gelston

Tags:

Electronic Enclosures,

Quality,

Plastic vs. metal,

Waterproofing,

plastic enclosures

SINCE 1993 MADE IN USA

SINCE 1993 MADE IN USA