The injection molding industry continues to evolve through the adoption of newly engineered plastic materials and emerging production technologies.

Current and Future Trends in Injection Molding: From Product Design to Materials and Manufacturing Technologies

Posted: November 30, 2023 by

Jon Gelston

Tags:

Plastic Injection Molding Defects,

Plastic Types,

Quality,

Texture,

Choosing the right plastic injection molder

Draft Angle in Plastic Injection Molding Explained: From Part Design to Finished Product

Posted: November 16, 2023 by

Jon Gelston

Tags:

Plastic Injection Molding Defects,

Plastic Types,

Quality,

Texture,

Choosing the right plastic injection molder

Draft angle is a critical concept in plastic injection molding. It directly affects both the quality and manufacturability of plastic parts, so it’s crucial to get it right from the start to avoid production issues down the line. Worse, it can be a detail that can render your injection mold useless.

Put simply, draft angle refers to the taper or angle that is designed into the vertical walls of a plastic part, relative to the vertical axis of the mold. Properly tapered walls ensure that the finished part can more easily eject from the mold after the forming process is complete. Essentially, an optimal draft angle is necessary because it prevents the part from getting stuck in the mold cavity due to the friction between the plastic material and the mold surfaces on the texture side and the suction between the plastic material and the mold surfaces on the interior side.

Common Applications for Insert Molding in Plastic Injection Molded Products

Posted: November 2, 2023 by

Jon Gelston

Tags:

Plastic Injection Molding Defects,

Plastic Types,

Quality,

Texture,

Choosing the right plastic injection molder

Insert molding is integral for many plastic injection molded products that require threaded connections, high-strength fasteners, or other metal components integrated straight into the plastic. While these complex part features could potentially be produced through injection molding alone, insert molding allows us to combine the increased strength and durability of metal with the flexibility of plastic molding.

Below, we take a look at some of the most common insert molded products, along with some of the advantages that metal inserts bring to the table.

A Guide to Optimizing Product Design for Plastic Injection Molding

Posted: October 19, 2023 by

Jon Gelston

Tags:

Plastic Injection Molding Defects,

Plastic Types,

Quality,

Texture,

Choosing the right plastic injection molder

Your custom injection molded products are only as good as the designs on which they are based. The injection molding process is delicate and complex, requiring precision designs and specifications to ensure a quality end product. Everything from the size and shape of the components to the strength requirements must be factored into the design in order to optimize the production process.

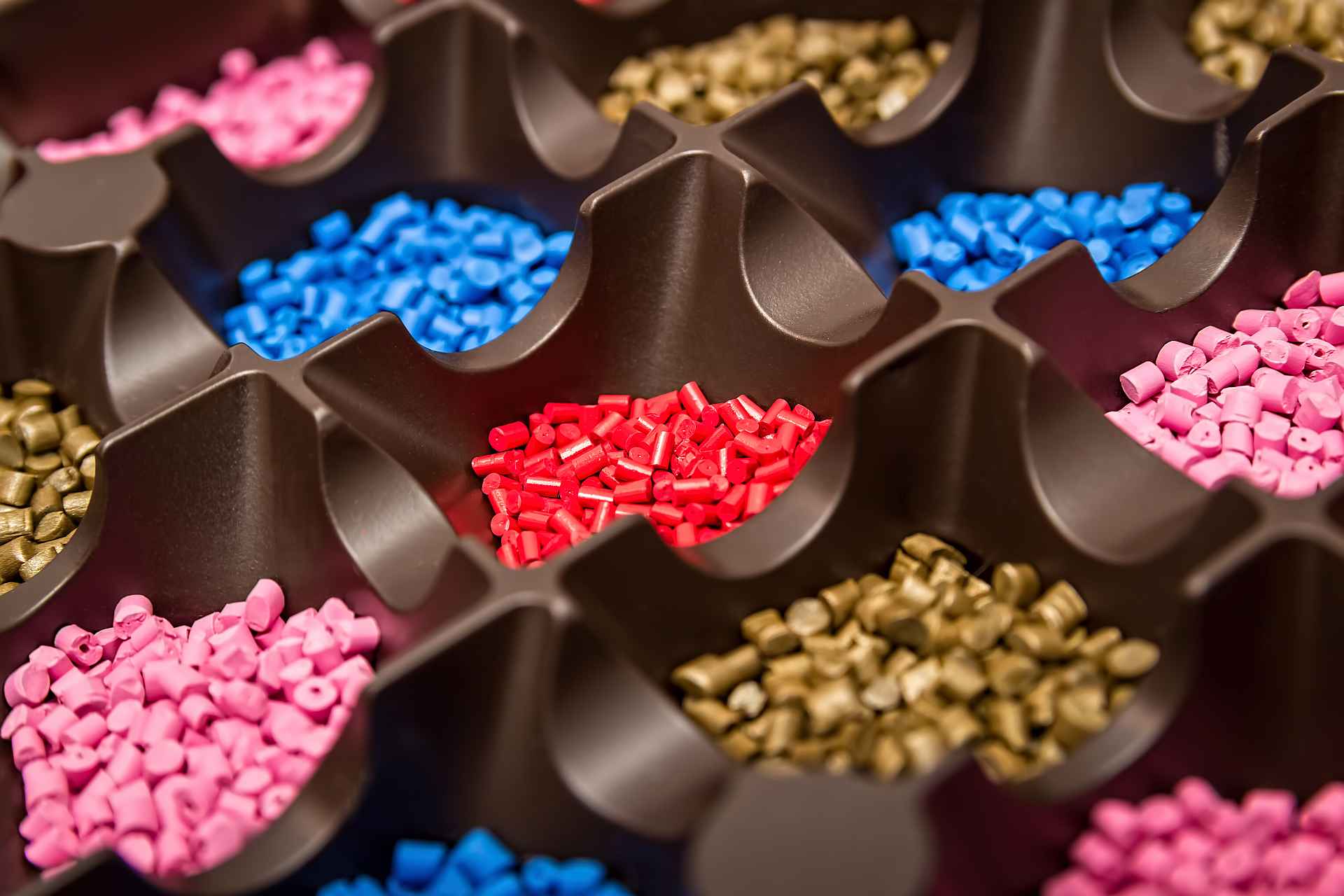

Moreover, there are a multitude of unique thermoplastic materials to choose from. In order to optimize your products for both cost and functional performance, we must consider (and sometimes test) numerous different materials in the design phase.

Understanding Material Choices in Plastic Product Design

Posted: October 5, 2023 by

Jon Gelston

Tags:

Plastic Injection Molding Defects,

Plastic Types,

Quality,

Texture,

Small Plastic Parts,

Choosing the right plastic injection molder

When it comes to designing custom injection molded products, choosing the right material is crucial. Optimum material choice ensures that the final products exhibit the quality and durability that you expect, as well as all of the desired performance aspects. Product costs are also often a major consideration in material choice.

Of course, there are a multitude of different injection molded plastics to choose from, each offering unique strengths and performance advantages. However, choosing the ideal molded plastic material isn’t always an obvious process. There are many complex material properties and production issues to consider.

The Role of User-Centered Design in Injection Molded Product Development

Posted: September 22, 2023 by

Jon Gelston

Tags:

Plastic Injection Molding Defects,

Plastic Types,

Quality,

Texture,

Small Plastic Parts,

Choosing the right plastic injection molder

In today's highly competitive and diverse market of molded plastics, ensuring success goes beyond the basic functionality and aesthetics of the products. While those aspects remain crucial, successful projects are backed up by a further understanding of their respective markets, their end users, and the unique needs they bring to the table.

This is where user-centered design (UCD) plays a pivotal role in plastic injection molding, considering the end-user experience first and foremost throughout product development. When combined with the precision and efficiency of the injection molding process, UCD can result in custom products that meet or exceed user expectations while also being as cost-effective and sustainable as possible.

Sustainability and Eco-Friendliness in Today’s Plastic Injection Molding Industry

Posted: September 7, 2023 by

Jon Gelston

Tags:

Plastic Injection Molding Defects,

Plastic Types,

Quality,

Plastic vs. metal,

Texture,

Small Plastic Parts,

Choosing the right plastic injection molder,

Nylon Injection Molding,

plastic injection molding Colorado

For at least the past decade, plastics have often been considered negatively in discussions concerning sustainability and eco-friendliness. But most of this is tied to single-use plastics and how they are handled after usage. Looking further upstream to plastic manufacturing, the reality may be more eco-friendly than one would think. The modern injection molding sector has become more and more concerned with sustainability and environmental friendliness. From the plastic materials that make up the products to the production equipment that molds them, along with all of the complex logistics behind shipping and supply chain management – today’s industry demands better sustainability at every turn.

The Role of AIM Processing in Colorado's Medical and Tech Industries

Posted: August 23, 2023 by

Jon Gelston

Tags:

Plastic Injection Molding Defects,

Plastic Types,

Quality,

Plastic vs. metal,

Texture,

Small Plastic Parts,

Choosing the right plastic injection molder,

Nylon Injection Molding

Plastic injection molding services are increasingly crucial within today’s medical and tech sectors. From state-of-the-art medical devices and specialized healthcare equipment to complex electronics components and everyday gadgets, molded plastic products can be found in virtually every facet of modern day life.

Of course, medicine, healthcare, electronics manufacturing, and the various tech industries are some of the fastest growing markets in Colorado and across the nation. More and more vendors in these niches are demanding the highest quality American injection molding companies to manufacture their products lean, reliably, and as sustainably as possible – all while simplifying their supply chains. Enter AIM Processing, one of the greater Colorado region’s leading injection molding service providers.

Plastic Injection Molding with Nylon: Material Strengths and Applications

Posted: August 10, 2023 by

Jon Gelston

Tags:

Plastic Injection Molding Defects,

Plastic Types,

Quality,

Plastic vs. metal,

Texture,

Small Plastic Parts,

Choosing the right plastic injection molder,

Nylon Injection Molding

Nylon is a highly versatile thermoplastic material that is used in many specific injection molding applications today. An extremely durable and chemically-resistant plastic, nylon is commonly used in automotive electronic connectors, protective casings, enclosures, metal replacement parts, and high-wear mechanical components.

Common Injection Molded Plastic Materials Compared

Posted: July 27, 2023 by

Jon Gelston

Tags:

Plastic Injection Molding Defects,

Plastic Types,

Quality,

Plastic vs. metal,

Texture,

Small Plastic Parts,

Choosing the right plastic injection molder,

vacuum forming

There are many different common types of plastics used in the injection molding industry today. And for many projects, there will be numerous suitable plastics to choose from.

Of course, choosing the best thermoplastic material for your project isn’t simply a case of going with the strongest and most durable option, or choosing the cheapest suitable material. You have to carefully consider the use cases for your end products, all of the performance requirements, potential reliability issues that may arise, as well as the overall material cost, availability, and sustainability.

SINCE 1993 MADE IN USA

SINCE 1993 MADE IN USA