AIM Processing is a company that is focused on quality, and we have been dedicated to giving personalized attention to each molding project for nearly 30 years. As a result, our team takes great care to ensure that every project is constructed using the best possible materials for the intended application use. Beyond plastic, however, it can also be important to choose the proper metal inserts to work alongside the molded material. Explore some factors to consider when working with metal inserts.

How to Select The Right Metal Inserts for Molded Plastics

Posted: November 29, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Injection Molding Tooling,

Plastic Injection Molding Defects,

Quality,

Plastic vs. metal,

Choosing the right plastic injection molder,

plastic enclosures

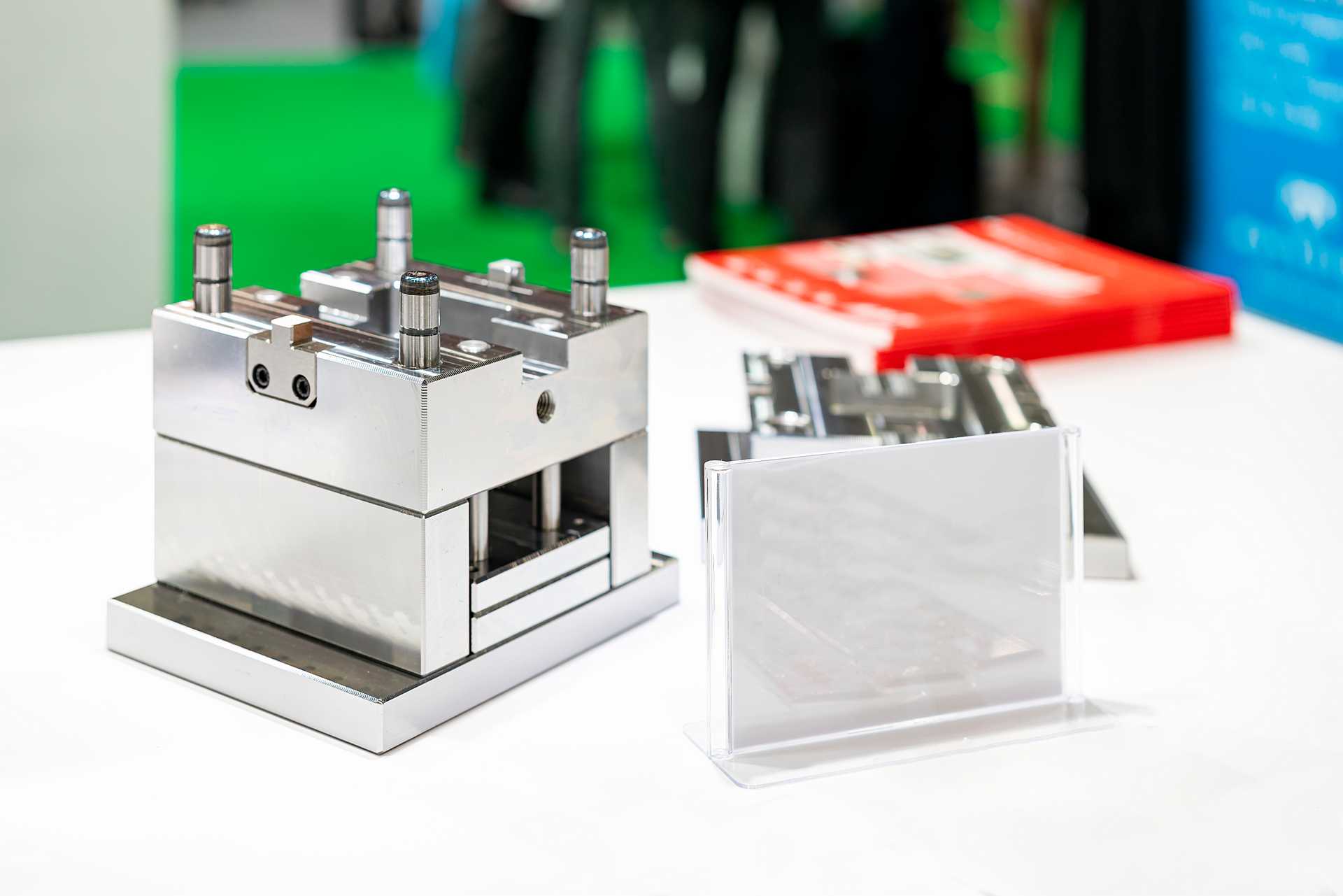

Overmolding & Insert Molding: Is There a Difference?

Posted: November 15, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Injection Molding Tooling,

Plastic Injection Molding Defects,

Quality,

Choosing the right plastic injection molder,

plastic enclosures

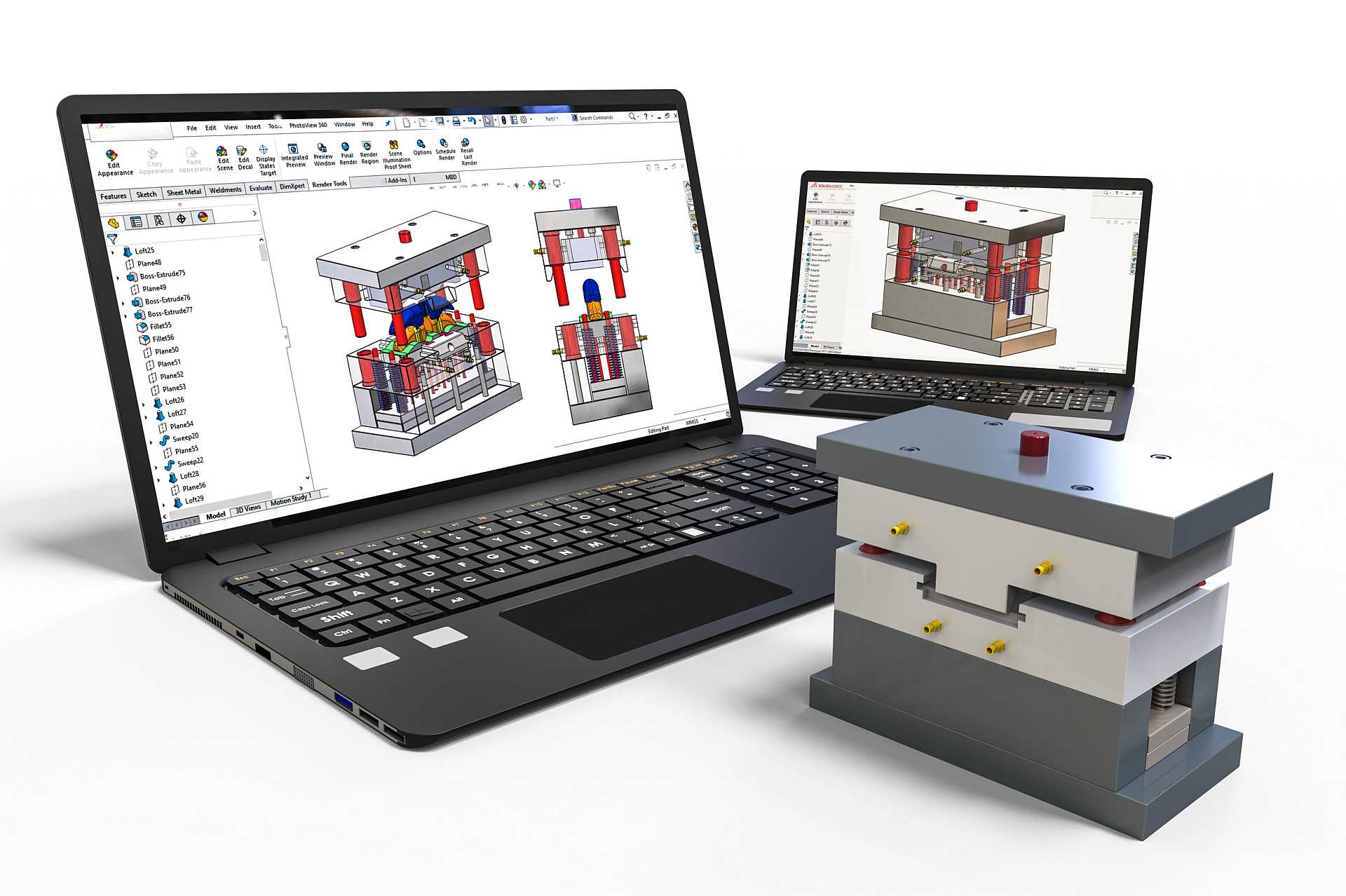

Thermoplastic Injection Mold Design for Electronic Enclosures

Posted: November 2, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Injection Molding Tooling,

Plastic Injection Molding Defects,

Quality,

Choosing the right plastic injection molder,

plastic enclosures

The Benefits of Injection Molded Parts

Posted: October 12, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Injection Molding Tooling,

Plastic Injection Molding Defects,

Quality,

Choosing the right plastic injection molder,

plastic enclosures

Plastic Injection Molding: Step by Step at AIM Processing

Posted: September 27, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Injection Molding Tooling,

Plastic Injection Molding Defects,

Quality,

Choosing the right plastic injection molder,

plastic enclosures

Most Common Injection Molding Defects and How to Prevent Them

Posted: September 14, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Injection Molding Tooling,

Plastic Injection Molding Defects,

Quality,

Choosing the right plastic injection molder,

plastic enclosures

5 Things No One Will Tell You About Custom Injection Molding

Posted: April 5, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Injection Molding Tooling,

Plastic Injection Molding Defects,

Plastic Types,

Small Plastic Parts,

Choosing the right plastic injection molder

Essential Guide to Custom Injection Molding

Posted: March 15, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

elastomeric overmolding,

insert molding,

Plastic Injection Molding Tooling,

Plastic Types,

Small Plastic Parts,

Choosing the right plastic injection molder

Creating Complex Parts With Overmolding and Insert Molding

Posted: February 25, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

elastomeric overmolding,

insert molding,

Plastic Injection Molding Tooling,

Plastic Types,

Small Plastic Parts,

Choosing the right plastic injection molder

Injection Molding 101: Plastic Injection Molding and Thermoplastics

Posted: December 9, 2021 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Injection Molding Tooling,

Choosing the right plastic injection molder

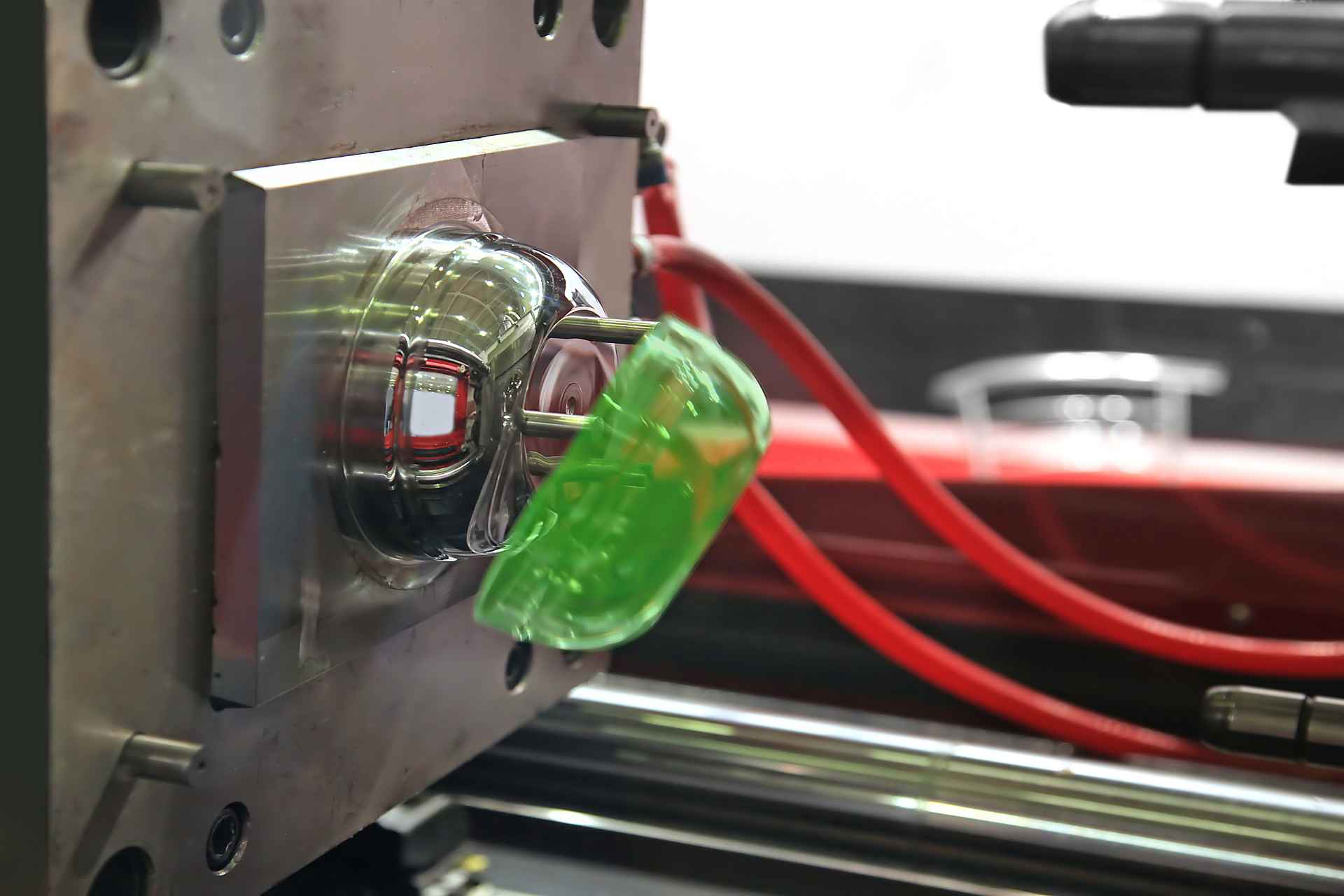

Thermoplastic injection molding is a common process used for the mass production of parts by using specialized machines. The technique works by injecting molten thermoplastic resin into a mold under high pressure, where it is held until cooled into solid form. If you have ever been curious to learn more about this important process, then you are in luck! Read through this guide and discover what is possible with thermoplastic injection molding.

.png)