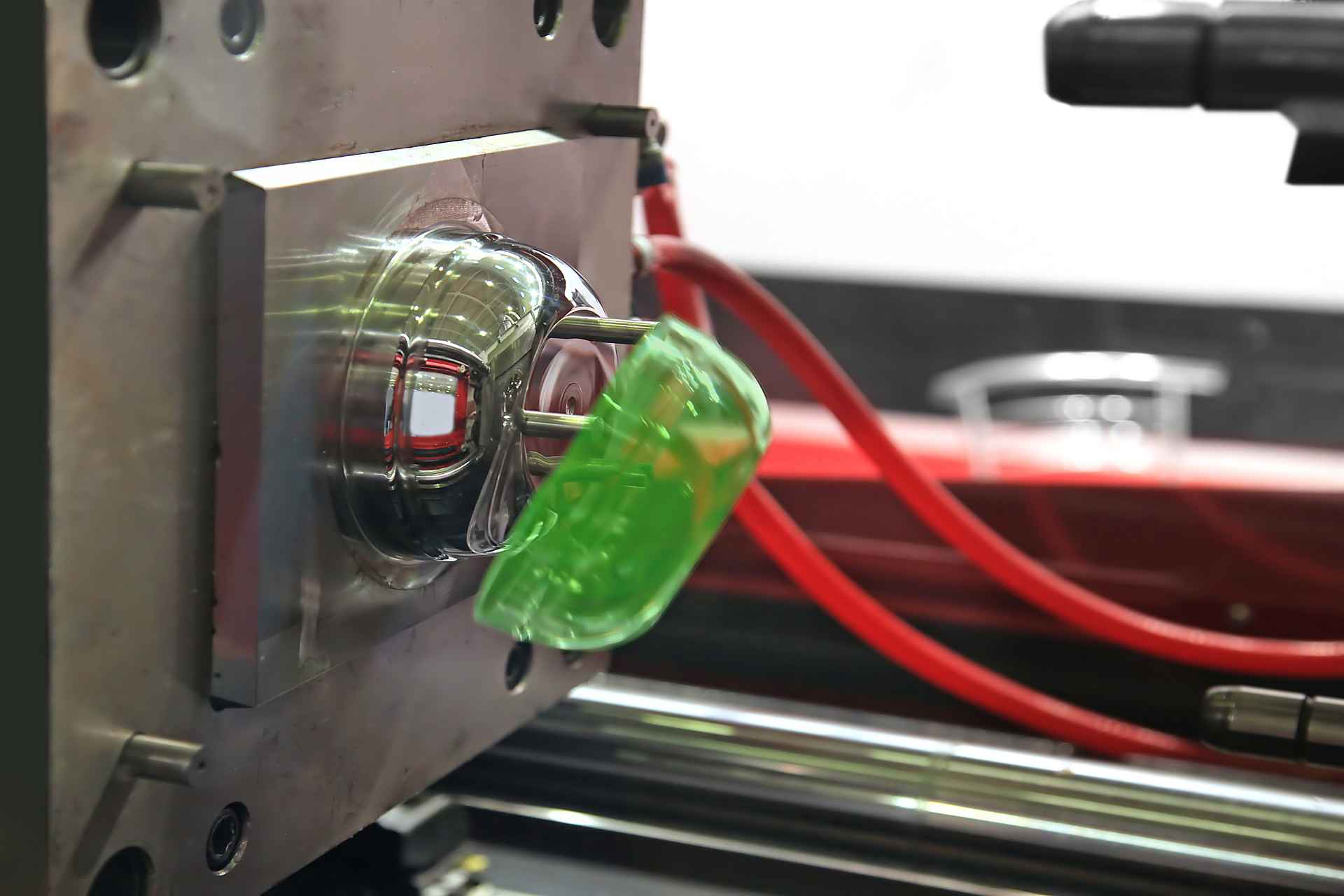

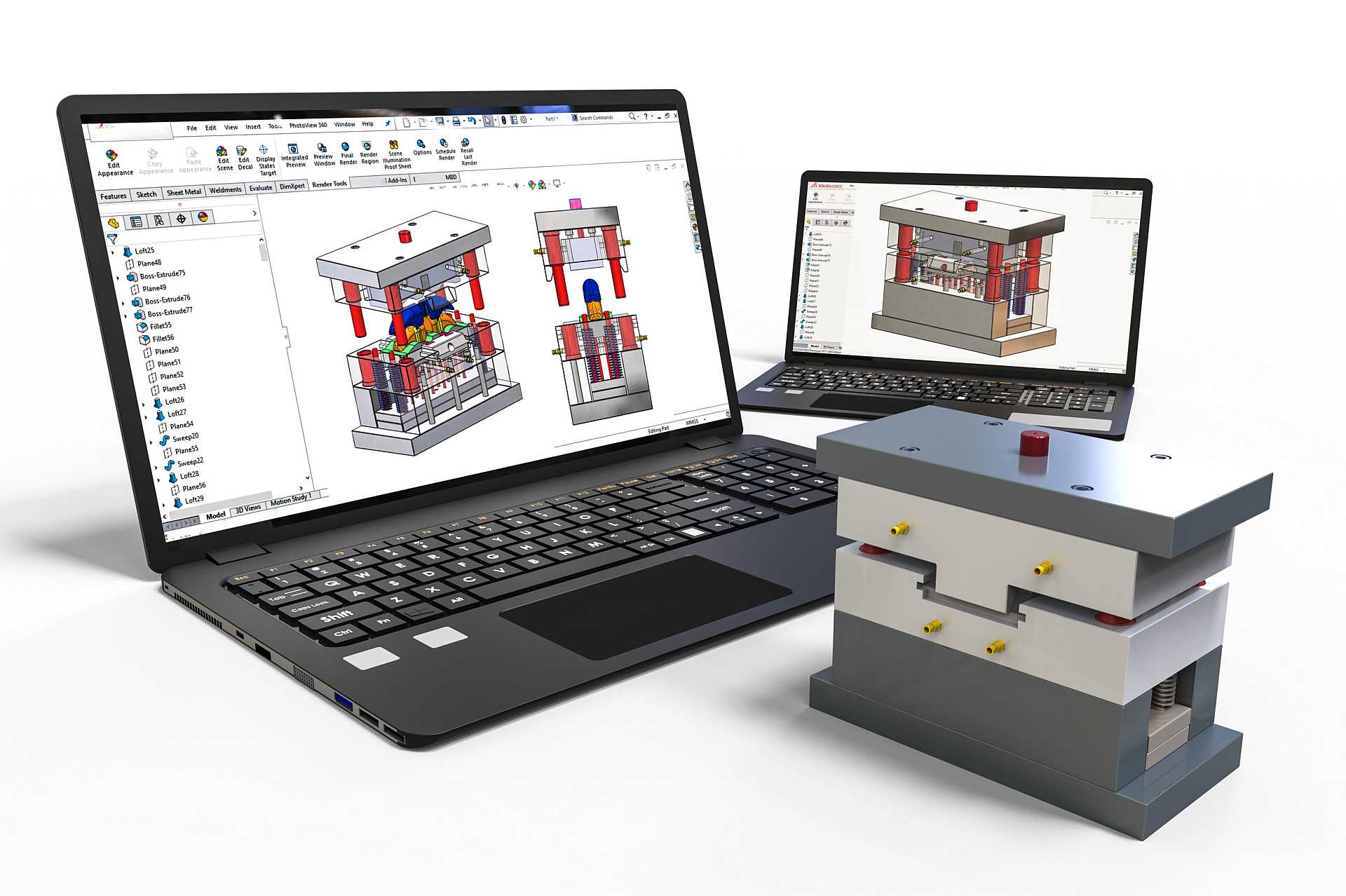

Injection molding services are an efficient, reliable, and cost-effective method to produce small plastic parts for a myriad of applications. From handheld consumer electronics and food/beverage utensils to state-of-the-art medical devices, plastic injection molding is a crucial capability throughout today’s manufacturing world.

Utilizing our specialized small part injection molding services, AIM Processing is able to manufacture small shapes and complex component geometries through an economical and highly repeatable process. This allows us to meet the unique needs of customers across numerous consumer, commercial, and industrial applications.

SINCE 1993 MADE IN USA

SINCE 1993 MADE IN USA