As a manufacturing manager, you know the frustration: Parts arriving with inconsistent quality. Missed delivery deadlines. Phone calls and emails going unanswered. Yet despite these issues, many managers feel trapped with their current injection molding partner because they possess the tooling needed to produce critical parts.

Tooling Transfer: Breaking Free from Underperforming Injection Molders

Posted: April 14, 2025 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Injection Molding Defects,

Tool Transfer

Three Tricks for Successful Demolding in Plastic Injection Molding

Posted: March 21, 2025 by

Jon Gelston

Tags:

Plastic Injection Molding,

Quality

In plastic injection molding, the process of demolding a part is as important as creating the mold design and forming the part. Successful demolding is essential for maintaining part quality, reducing mold damage and minimizing cycle times. To optimize the process, here are three crucial tricks to enable a clean release from the mold without creating defects in the part. These recommendations will generate more consistent and efficient demolding.

Sinking in Sink Marks?

Posted: February 10, 2025 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Injection Molding Defects,

Quality

How to avoid them and produce high-quality injection molded parts

Injection molding creates complex plastic parts with high precision and repeatability. However, like any manufacturing process, it comes with its challenges, including defects in the molded part. One of the most common defects is sink marks. These small surface depressions can compromise not only the aesthetic appeal of a product but also its functionality. This blog will describe sink marks, explain what causes them to occur and offer methods to prevent these defects.

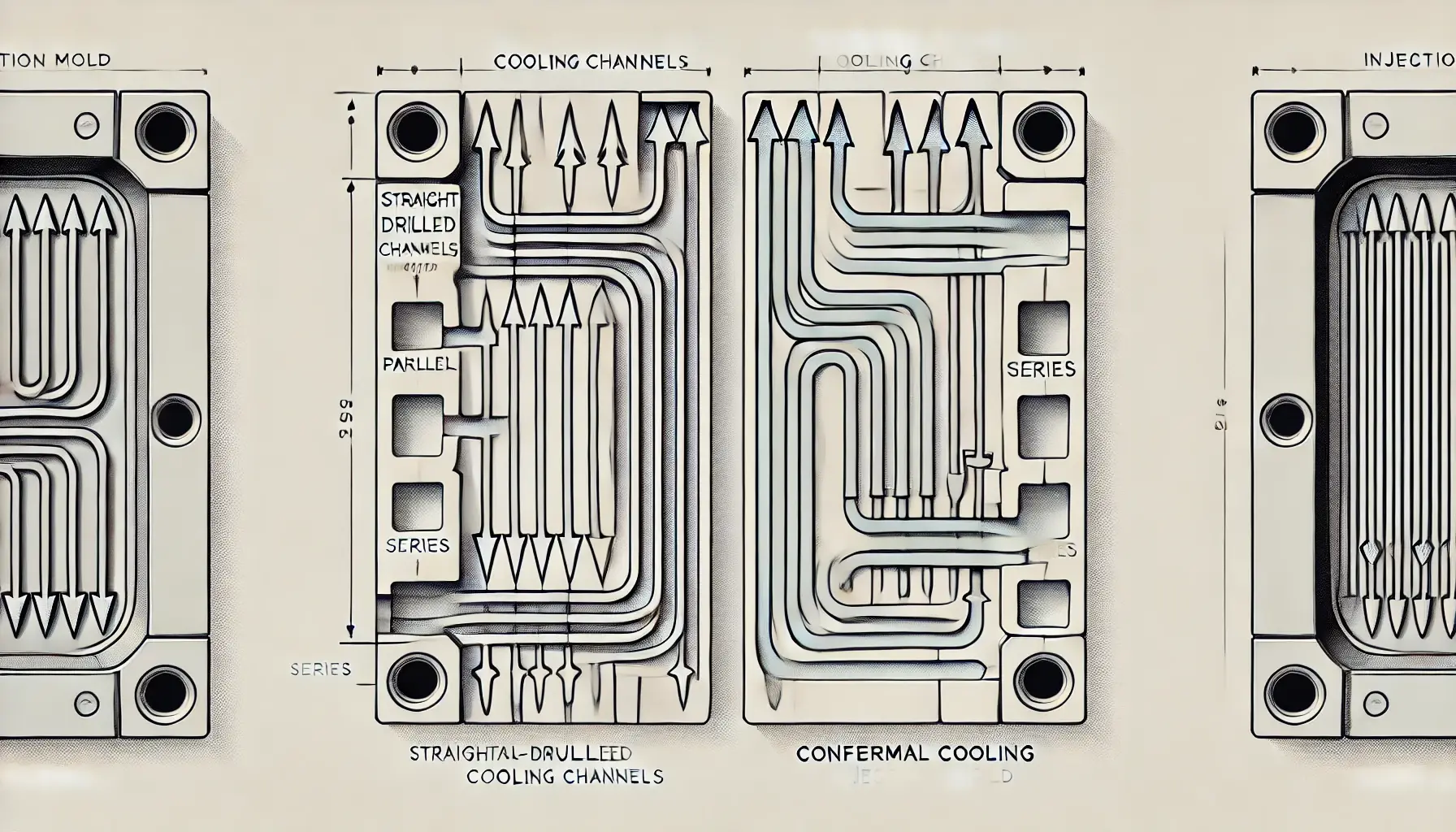

Designing Cooling Channels in Injection Molds: A Combination of Art and Science

Posted: December 4, 2024 by

Jon Gelston

Tags:

Plastic Injection Molding,

Quality,

injection molding

Cooling the molten plastic injected into the mold in a plastic injection molding machine is a critical process. The cooling system controls the temperature of the mold and impacts the quality and forming efficiency of the injection molded product. Uneven temperatures in the mold create temperature differentials in different sections of the product. The varying temperature across the product can cause temperature-induced stress, shrinkage, warping and deformation. Products with complex shapes and uneven wall thickness are particularly susceptible to these effects if the temperature distribution is uneven. An efficient cooling system that can maintain a uniform temperature distribution can minimize these defects in the molded parts. This article will present both options and recommendations for designing effective cooling channels in injection molds and explore strategies and considerations crucial for maximizing cooling efficiency and optimizing molding outcomes.

Voice of the Customer: Empowering Medical Device Innovation Through Precision Manufacturing

Posted: October 29, 2024 by

Jon Gelston

Tags:

Plastic Injection Molding,

Quality,

Tool Transfer,

Customer

A minimally invasive medical procedure or device simplifies traditional treatment methods, causing the patient less pain and reducing the risk of complications. When Trice Medical was experiencing unnecessary complications and frustrations obtaining critical injection molded components for its manufactured equipment, it realized the need for a new business partner that could supply a reliable, painless solution. Recently, President of Trice Medical, Mike Steen, sat down to discuss his company's long-standing partnership with AIM Processing. With more than 15 years of experience in the industry, Mike shared valuable insights into the strong collaboration between the two companies, the value AIM Processing brings to the table and how their partnership has evolved over time.

Join AIM Processing at the 2024 Design-2-Part Manufacturing Trade Show in Long Beach, CA

Posted: August 20, 2024 by

Jon Gelston

Tags:

Plastic Injection Molding,

Tradeshow and Events

We are thrilled to announce that AIM Processing will be exhibiting at the 2024 Long Beach Manufacturing Trade Show in September! This premier event is a fantastic opportunity to showcase our innovative solutions and connect with manufacturing engineers, design engineers, manufacturing management and other industry professionals.

How Colorado Injection Molding Is Transforming the Industry

Posted: May 17, 2023 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Types,

Quality,

Small Plastic Parts,

Choosing the right plastic injection molder

For more than 50 years, the Colorado region has been a national hotspot for the injection molding industry. Throughout the decades, our state has served as one the nation’s primary bases in providing the custom toolmaking and injection molding services which are critical for manufacturing so many of today’s plastic products.

Injection Molding Companies in Colorado: The Benefits of Local Manufacturing

Posted: May 2, 2023 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Types,

Quality,

Small Plastic Parts,

Choosing the right plastic injection molder

The demand for quality American injection molding services continues to rise in 2023, with an increasing number of domestic sellers onshoring some or all of their plastic manufacturing operations. Colorado is no exception, continuing to evolve into a nexus for the state-of-the-art plastic molding industry.

Of course, reshoring is partly a response to international supply chain disruptions which have impacted higher level manufactured products over the last several years. Many customers are simply looking for a more reliable manufacturing partner that offers a more dependable supply chain. However, it’s also largely an embrace of the superior quality, convenience, and customer service that Colorado’s injection molding companies can offer.

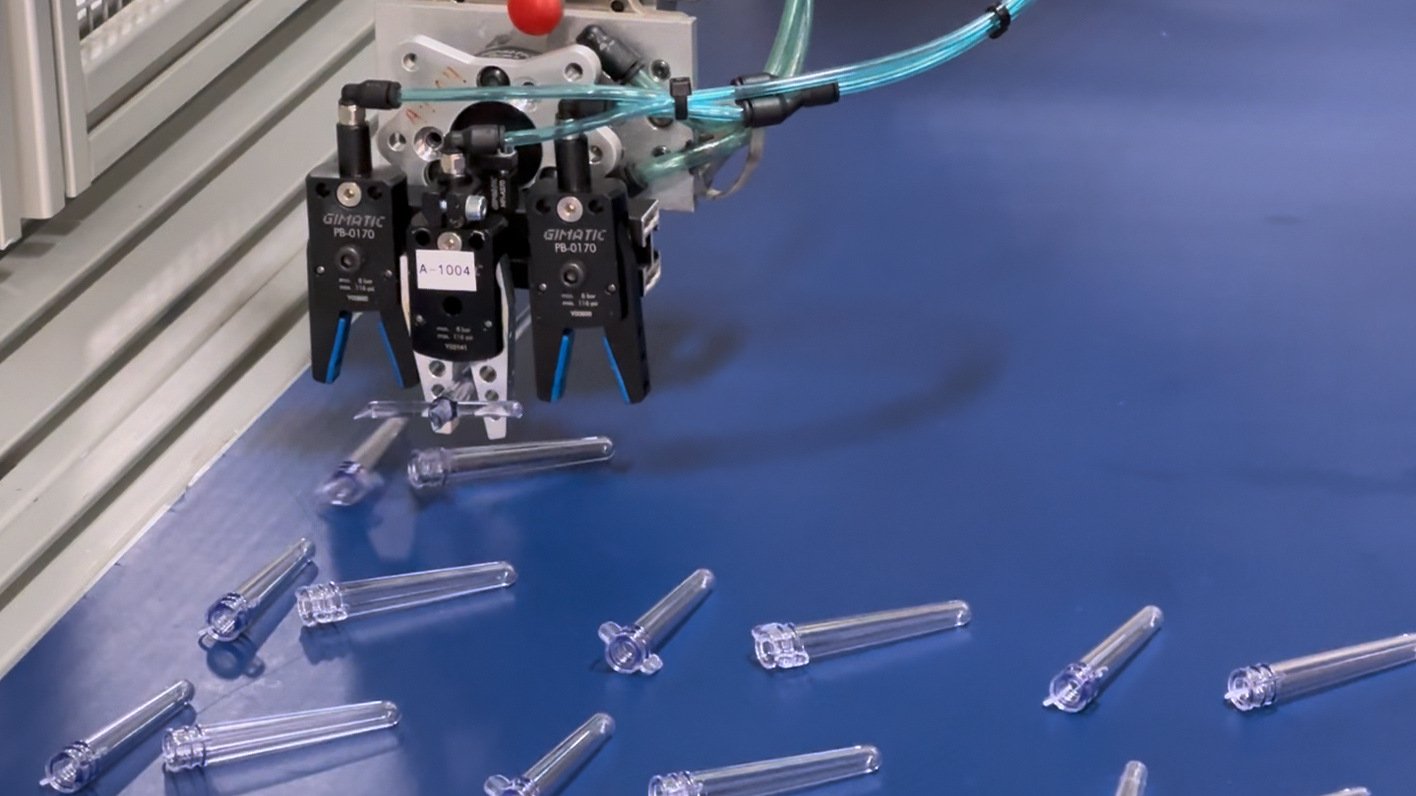

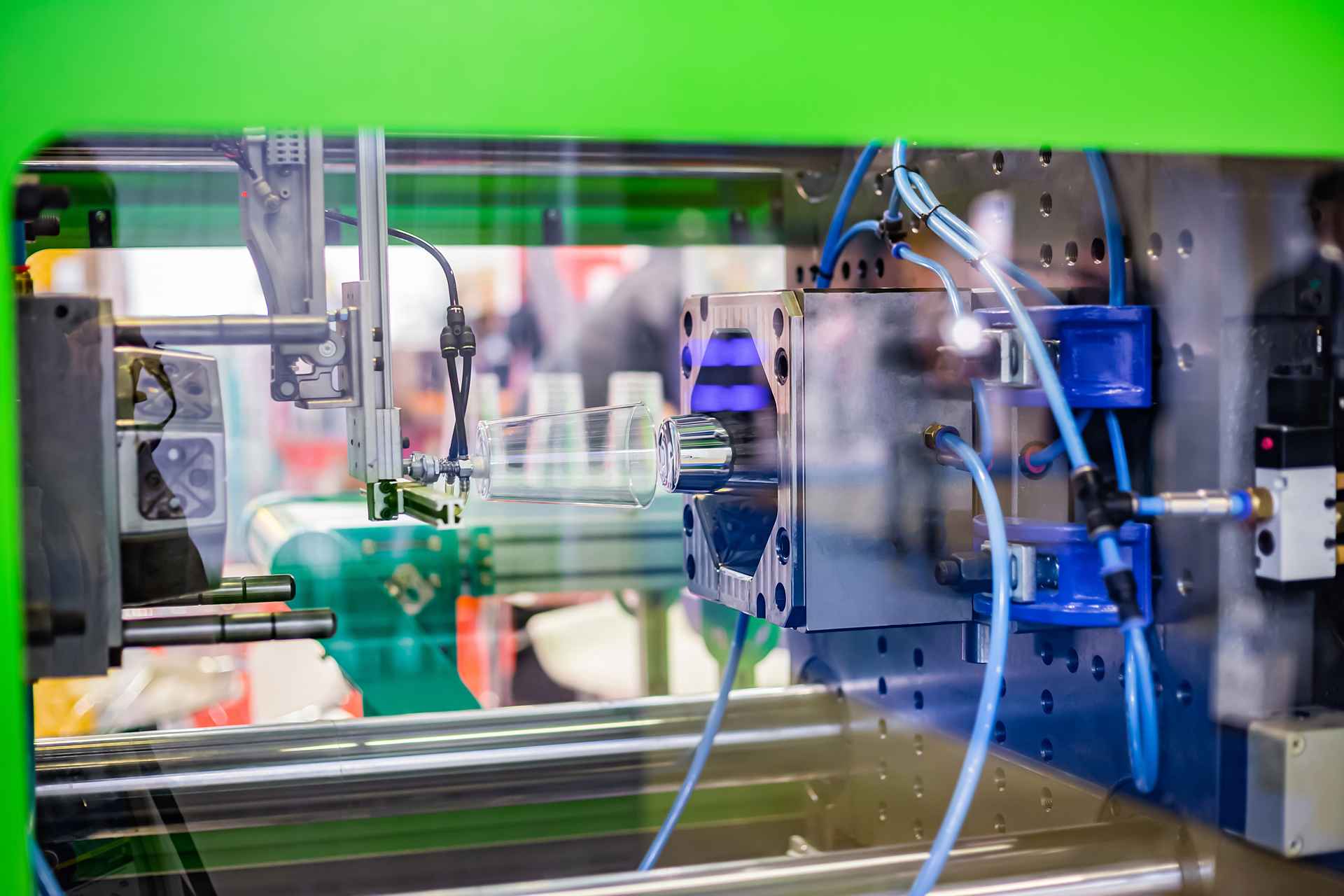

Automation in Injection Molding: Making the US Globally Competitive

Posted: April 20, 2023 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Types,

Quality,

Small Plastic Parts,

Choosing the right plastic injection molder

Automated production technology has become increasingly common throughout the American manufacturing sector – and the plastic injection molding service industry is no exception. New automation technology allows domestic manufacturers to be substantially more efficient and more productive, and thus more cost-competitive with their overseas counterparts.

How to Select The Right Metal Inserts for Molded Plastics

Posted: November 29, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Injection Molding Tooling,

Plastic Injection Molding Defects,

Quality,

Plastic vs. metal,

Choosing the right plastic injection molder,

plastic enclosures

AIM Processing is a company that is focused on quality, and we have been dedicated to giving personalized attention to each molding project for nearly 30 years. As a result, our team takes great care to ensure that every project is constructed using the best possible materials for the intended application use. Beyond plastic, however, it can also be important to choose the proper metal inserts to work alongside the molded material. Explore some factors to consider when working with metal inserts.

SINCE 1993 MADE IN USA

SINCE 1993 MADE IN USA