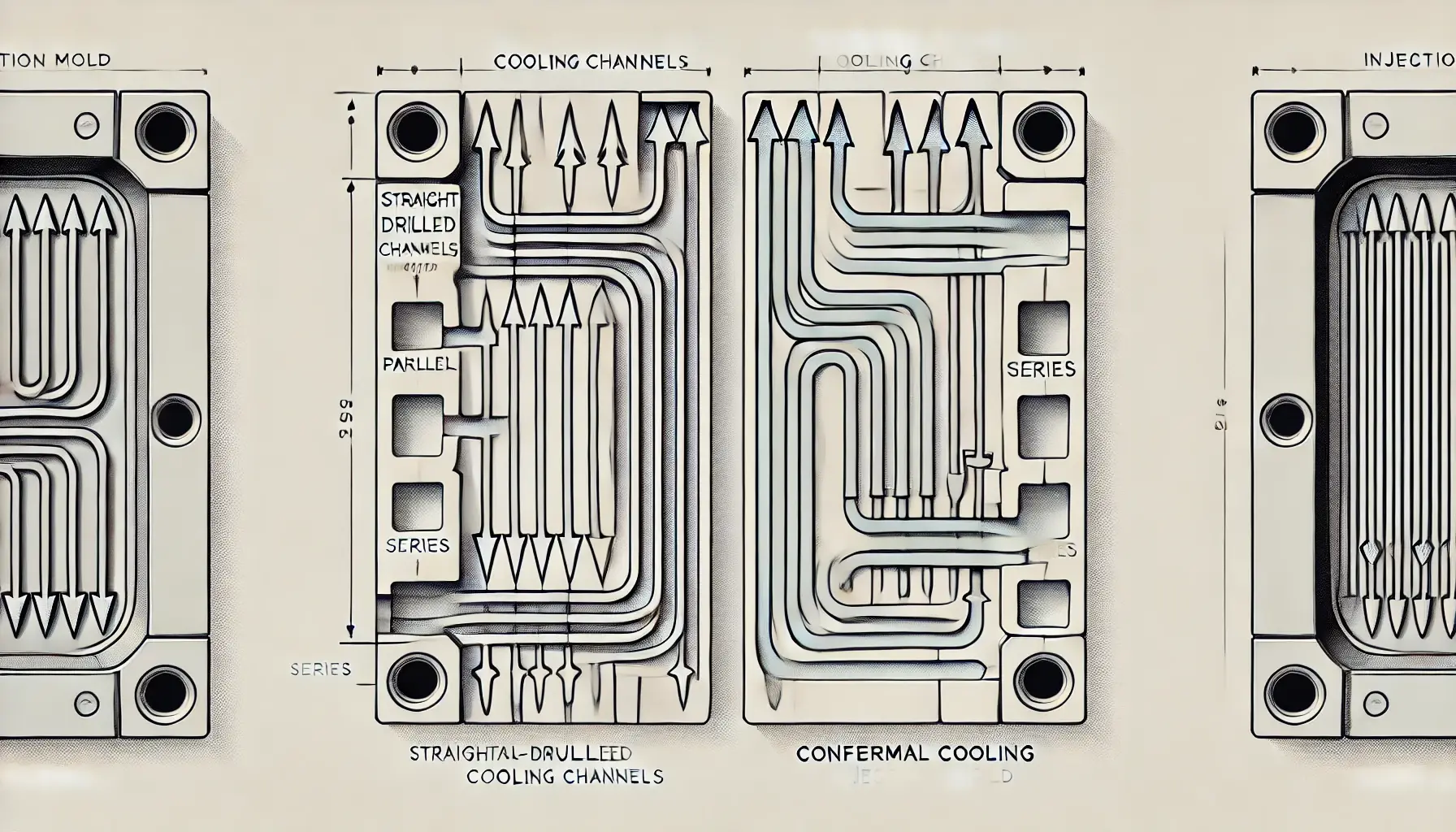

Cooling the molten plastic injected into the mold in a plastic injection molding machine is a critical process. The cooling system controls the temperature of the mold and impacts the quality and forming efficiency of the injection molded product. Uneven temperatures in the mold create temperature differentials in different sections of the product. The varying temperature across the product can cause temperature-induced stress, shrinkage, warping and deformation. Products with complex shapes and uneven wall thickness are particularly susceptible to these effects if the temperature distribution is uneven. An efficient cooling system that can maintain a uniform temperature distribution can minimize these defects in the molded parts. This article will present both options and recommendations for designing effective cooling channels in injection molds and explore strategies and considerations crucial for maximizing cooling efficiency and optimizing molding outcomes.

SINCE 1993 MADE IN USA | ISO 9001:2015 | Call Us: 303.684.0931

SINCE 1993 MADE IN USA | ISO 9001:2015 | Call Us: 303.684.0931