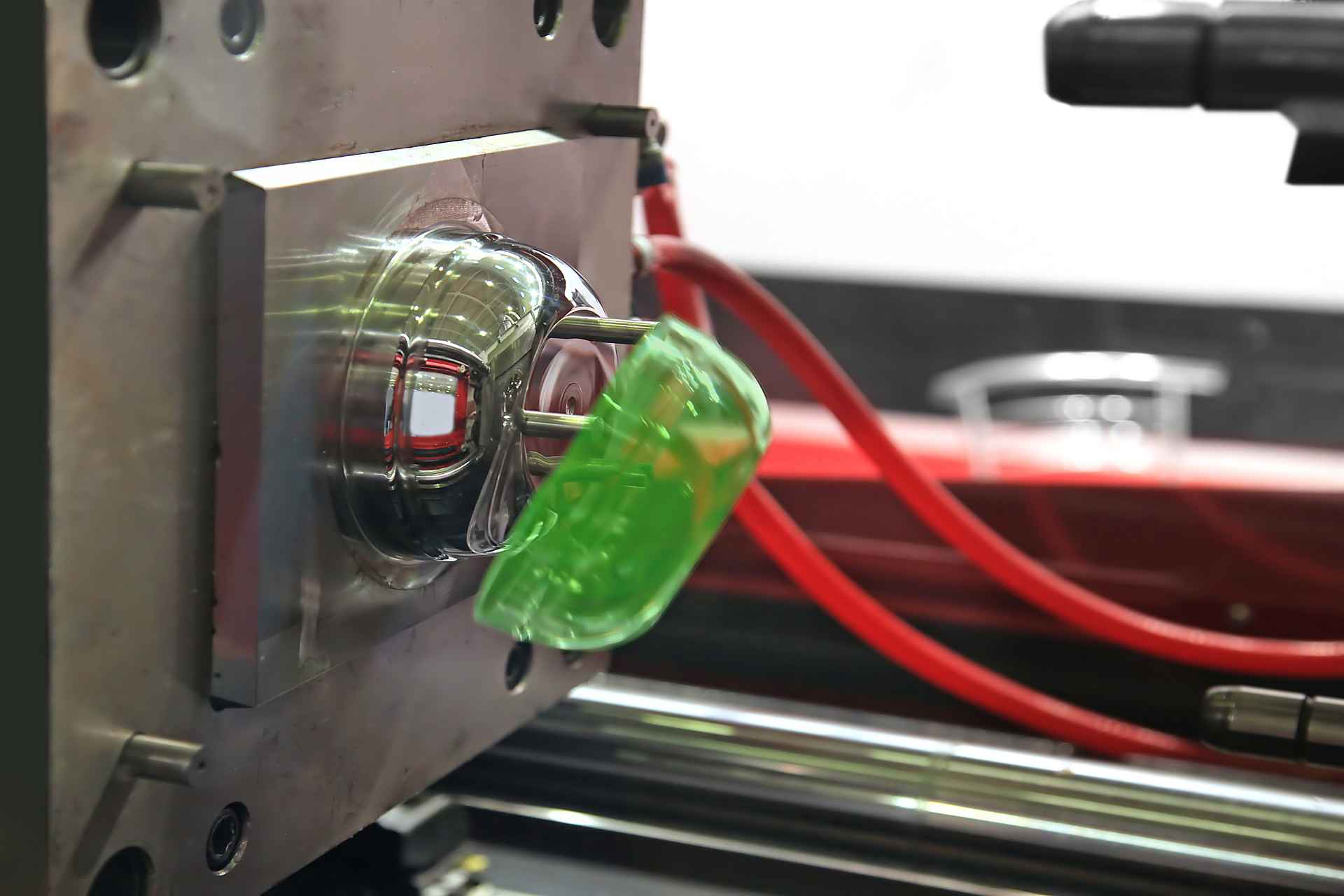

Plastic injection molding services are a reliable, efficient, and scalable method for manufacturing an extremely wide range of different small parts and components. However, like all production methods, the injection molding process poses some unique challenges for small plastic part manufacturers.

In this article, we discuss some of the most common challenges and quality control issues that can arise with custom injection molded products. At AIM Processing, we apply decades of combined engineering expertise and utilize the latest production technology to overcome these challenges, delivering superior injection molded products which are manufactured to your exact specifications.The Challenges of Small Part Injection Molding

Posted: March 21, 2023 by

Jon Gelston

Tags:

Plastic Gate Design,

Plastic Injection Molding Defects,

Plastic Types,

Quality,

Plastic vs. metal,

Texture,

Small Plastic Parts,

Choosing the right plastic injection molder

The Best Uses for Small Part Injection Molding

Posted: March 1, 2023 by

Jon Gelston

Tags:

Plastic Gate Design,

Plastic Injection Molding Defects,

Plastic Types,

Quality,

Plastic vs. metal,

Texture,

Small Plastic Parts,

Choosing the right plastic injection molder

Small part injection molding is an efficient and economical manufacturing method used across many different industries and product categories.

When compared to traditional casting methods or 3D printing, plastic injection molding is quicker to set up and easier to scale. Furthermore, the injection molding process is highly automatable, making it ideal for today’s domestic customers in search of a more flexible and reliable supply chain solution.

Small Part Injection Molding: Who Uses It?

Posted: February 21, 2023 by

Jon Gelston

Tags:

Plastic Injection Molding Defects,

Electronic Enclosures,

Quality,

Plastic vs. metal,

Choosing the right plastic injection molder,

plastic enclosures,

Outdoor enclosures

Injection molding services are an efficient, reliable, and cost-effective method to produce small plastic parts for a myriad of applications. From handheld consumer electronics and food/beverage utensils to state-of-the-art medical devices, plastic injection molding is a crucial capability throughout today’s manufacturing world.

Utilizing our specialized small part injection molding services, AIM Processing is able to manufacture small shapes and complex component geometries through an economical and highly repeatable process. This allows us to meet the unique needs of customers across numerous consumer, commercial, and industrial applications.

How to Select The Right Metal Inserts for Molded Plastics

Posted: November 29, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Injection Molding Tooling,

Plastic Injection Molding Defects,

Quality,

Plastic vs. metal,

Choosing the right plastic injection molder,

plastic enclosures

AIM Processing is a company that is focused on quality, and we have been dedicated to giving personalized attention to each molding project for nearly 30 years. As a result, our team takes great care to ensure that every project is constructed using the best possible materials for the intended application use. Beyond plastic, however, it can also be important to choose the proper metal inserts to work alongside the molded material. Explore some factors to consider when working with metal inserts.

Overmolding & Insert Molding: Is There a Difference?

Posted: November 15, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Injection Molding Tooling,

Plastic Injection Molding Defects,

Quality,

Choosing the right plastic injection molder,

plastic enclosures

Thermoplastic Injection Mold Design for Electronic Enclosures

Posted: November 2, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Injection Molding Tooling,

Plastic Injection Molding Defects,

Quality,

Choosing the right plastic injection molder,

plastic enclosures

The Benefits of Injection Molded Parts

Posted: October 12, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Injection Molding Tooling,

Plastic Injection Molding Defects,

Quality,

Choosing the right plastic injection molder,

plastic enclosures

Plastic Injection Molding: Step by Step at AIM Processing

Posted: September 27, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Injection Molding Tooling,

Plastic Injection Molding Defects,

Quality,

Choosing the right plastic injection molder,

plastic enclosures

Most Common Injection Molding Defects and How to Prevent Them

Posted: September 14, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Injection Molding Tooling,

Plastic Injection Molding Defects,

Quality,

Choosing the right plastic injection molder,

plastic enclosures

SINCE 1993 MADE IN USA

SINCE 1993 MADE IN USA