There are many advantages to working with injection molded parts. These advantages only increase when you choose to work with a molding company renowned for their high-quality products and personable customer service. AIM Processing is proud to be this type of reputable molding company. As such, we invite you to explore just a few of the ways you could potentially benefit from working with injection molded parts:

Complex Geometries

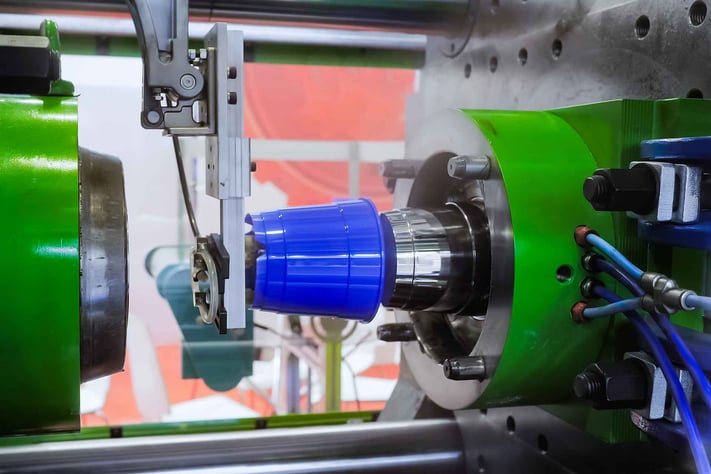

Injection molding is unique in that this process allows for tight tolerances that would otherwise be difficult to accomplish in such a rapid method of manufacturing. Tolerances are often +/- 0.005” or the diameter of a human hair. Some materials allow for even tighter tolerances. With a disciplined approach to tool and process development, very complex parts are possible. Screwing/unscrewing threads, ultrasonic welding ribs, and latching features are a few of the many geometries possible with injection molding.

Wide Range of Materials

With a number of details to take into account, from production costs to aesthetic preferences, parts designers will appreciate the flexibility that injection molding provides. Parts may have unique requirements beyond color, cost, and strength. Electrical resistivity, flammability rating, weatherability, biocompatibility, and chemical resistance are just a few of the many properties that a designer can evaluate to the part’s purpose. There are more than 100,000 identified grades of plastic suited to injection molding. Materials may differ by their cost and availability, so working with a molder who can help you through the material selection process is a must to find the one that’s right for you.

Efficiency

Injection molding is a quick process in comparison to alternative production methods. Neither 3D printing or CNC machining comes close to matching the speed at which most injection molding cycles can be completed. Most cycle times are in the range of 20-45 seconds, depending on the material, the part geometry, and dimensional requirements. In the most time-consuming examples, parts with complex geometry or thick walls, generally only require about 120 seconds to mold. In comparison, 3D printing can at times take hours to complete. This injection molding speed is never at the expense of quality however, making the process incredibly efficient and reliable.

High Repeatability

Plastic injection molding is most well known for its high repeatability. A properly designed part, using a properly made tool, in a properly maintained machine, with a properly defined process will produce a very consistent product. Once the original mold for the part has been designed and built, a properly built tool can last for 1 million+ cycles if maintained well. Because every part is created from the same mold, the entire batch can be relied upon for precise uniformity. Injection molding is the go-to method for volume manufacturing.

Lowers Waste and Lowers Costs

Injection molding generates less material waste than machining. Even though this process does still create some scrap, this excess material is not wasted. Any additional scrap produced during the injection molding process can be reground and reused for future injection molded parts when a customer permits it. Furthermore, injection molding not only reduces material costs, but also lowers labor costs due to a streamlined production process. If parts and tooling are designed to run automatically without labor content, then production costs are low and stay that way. This is what makes injection molding a globally competitive business.

SINCE 1993 MADE IN USA

SINCE 1993 MADE IN USA