When fast approaching deadlines and material availability concerns are at hand, the last thing that a customer wants to deal with is an order of injection molded parts to be delivered with defects. These quality issues can take many forms, which is why it is necessary to work with a molder that is well-versed in the common issues that can arise during production.

Injection Molded Part Defects: Blush

One of the most common injection molding defects is blush, which is the cloudy discoloration that may be found around injection gates or throughout the molded part. While this defect gets its name from the discoloration that occurs, the issue it causes is more than an aesthetic defect. Blushing can indicate a weak molded structure, alerting injection molders that their component could perform poorly when put to use.

There are several different potential causes for gate blush, which is why it is important to work with experts who can verify each stage of manufacturing. For example, improperly sized gates paired with incorrect material types will cause blushing fairly easily, but by adjusting the relative thickness of the molded part or by adjusting the molding tool’s nozzle diameter, the molding process can return to proper working order. Furthermore, factors such as incorrect melting temperatures or poorly positioned gates are other easily remedied reasons for blushing.

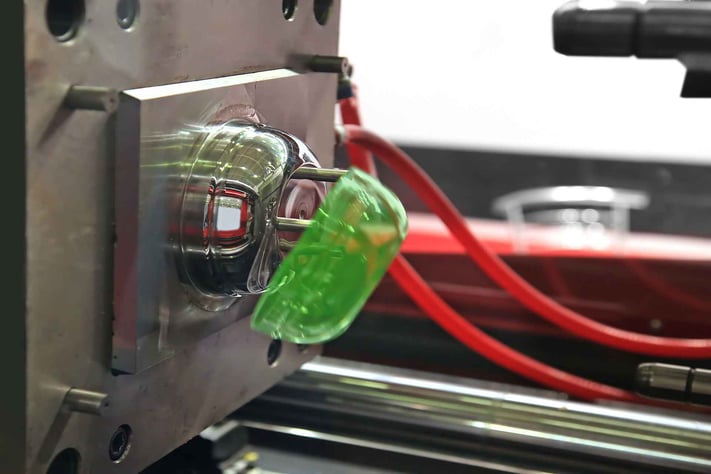

Injection Molded Part Defects: Flash

Flash is another common injection molding defect. This defect can occur when material leaks into the parting line (the split between mold halves), across a hole, or into a side feature to make a thin region of undesired plastic. Flash can be the result of too much pressure during the molding cycle, undersized injection molding machine, tool wear/damage, or an improperly designed/built tool. A professional will know the difference.

Injection Molded Part Defects: Sink

Sink marks will occur when the inner material of a molded part shrinks and pulls the outer surface wall inward. This defect leads to material depressions that impact the functionality of some molded components.

The first way to avoid sinks is through part design, avoiding inconsistent wall thicknesses. The second way to avoid sinks is to gate into the thickest section of the part so that you can continue to pump material in as it cools. The third way to avoid sinks is to go through a disciplined process development to determine the proper pack pressure and pack time.

Injection Molded Part Defects: Burns

Burning, also known as dieseling, typically appears as black or rust-colored discoloration on an edge or surface of a molded plastic part. Burn marks generally don’t affect part integrity, unless the plastic is burned to the extent of degradation.

Trapped air is the most common reason for overheating during the custom injection molding process. Because of this, it is useful for molders to utilize larger gas vents during manufacturing to allow air to escape as necessary. To avoid air becoming trapped in the first place, it can also be useful to reduce injection speeds of the molding material. Tool vents can wear and hob in, which can reduce their effectiveness. A professional can help determine how to diagnose and fix the problem.

Avoid Injection Molded Part Defects By Working with the Best

By utilizing their time-tested industry knowledge, molding experts are able to detect and avoid everything from minor surface defects to extreme defects that compromise overall product functionality. AIM Processing is one of the most dependable injection molding experts, and as such we are able to produce parts that are free from the most common defects listed above, as well as detect and solve rarer defects before they are delivered to customers.

SINCE 1993 MADE IN USA

SINCE 1993 MADE IN USA