Jon Gelston

Recent Posts

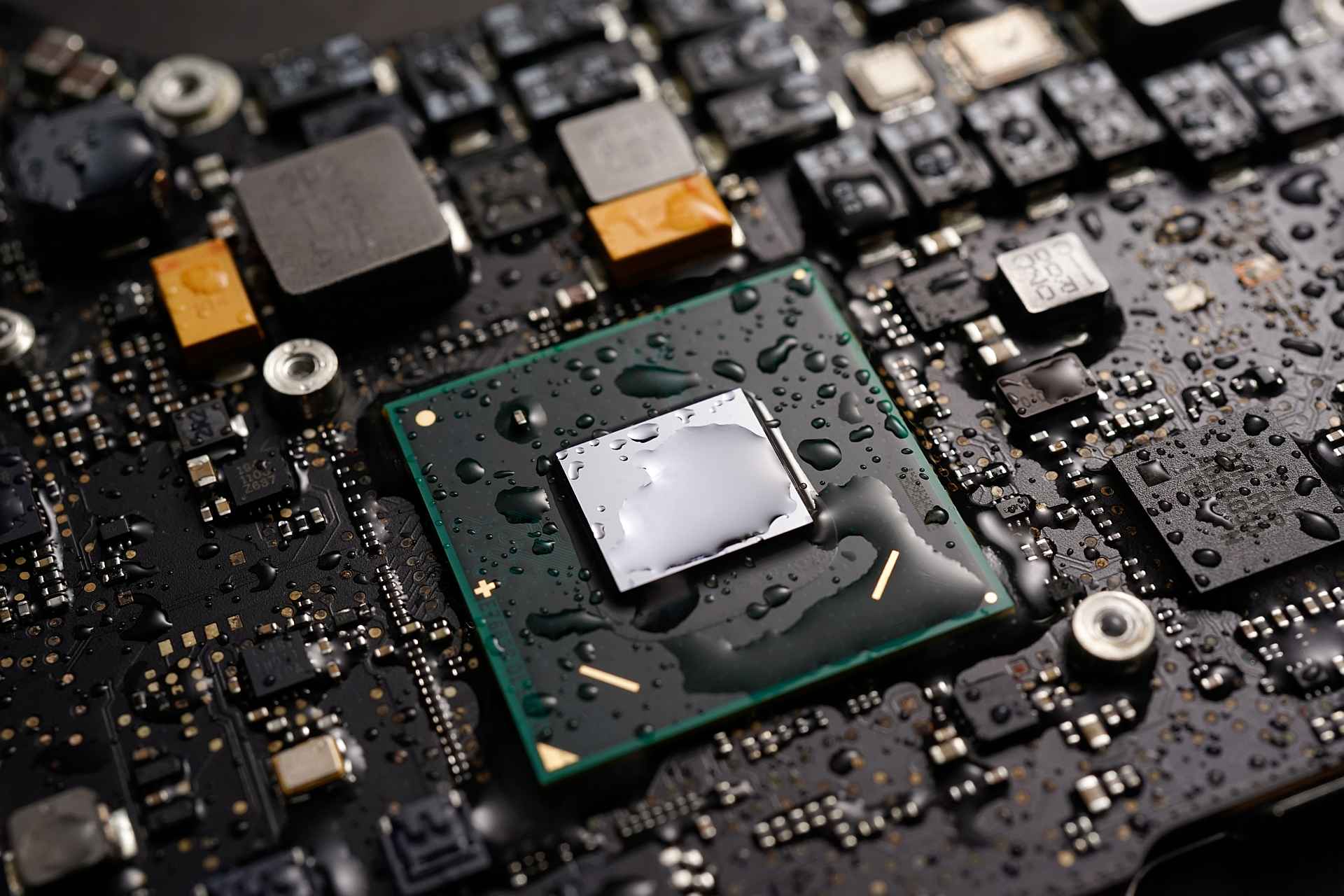

Mistakes To Avoid When Waterproofing Electronic Devices

Posted: April 19, 2022 by

Jon Gelston

Tags:

Electronic Enclosures,

Quality,

Waterproofing,

Assemblies

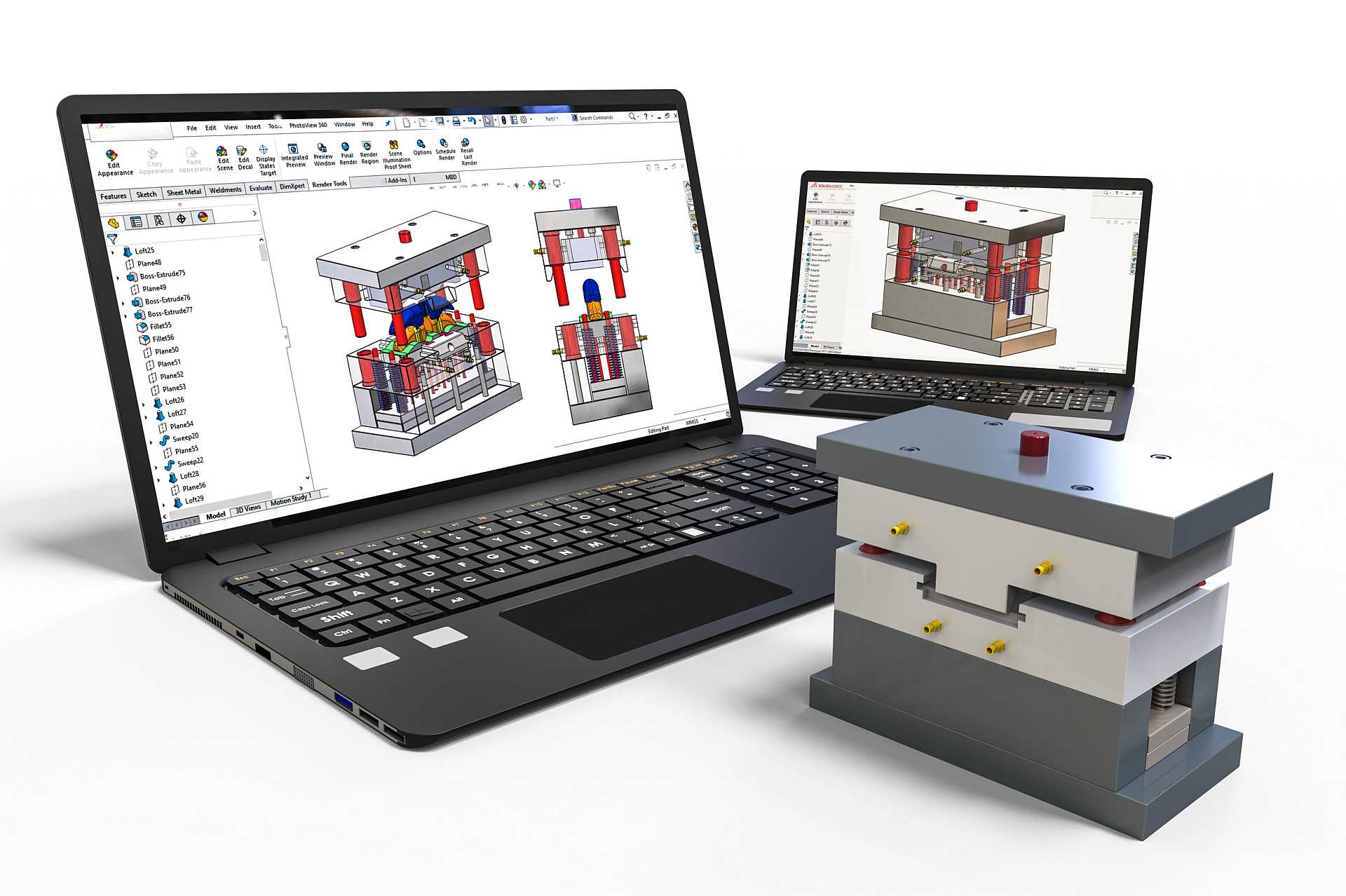

5 Things No One Will Tell You About Custom Injection Molding

Posted: April 5, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Injection Molding Tooling,

Plastic Injection Molding Defects,

Plastic Types,

Small Plastic Parts,

Choosing the right plastic injection molder

Essential Guide to Custom Injection Molding

Posted: March 15, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

elastomeric overmolding,

insert molding,

Plastic Injection Molding Tooling,

Plastic Types,

Small Plastic Parts,

Choosing the right plastic injection molder

Creating Complex Parts With Overmolding and Insert Molding

Posted: February 25, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

elastomeric overmolding,

insert molding,

Plastic Injection Molding Tooling,

Plastic Types,

Small Plastic Parts,

Choosing the right plastic injection molder

5 Major Advantages to Using Plastic Injection Molding for Manufactured Parts

Posted: February 4, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Types,

Small Plastic Parts

Insert Molding, Ultrasonic Welding, or Heat Staking: Which One Should I Use?

Posted: January 21, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Types,

Small Plastic Parts

10 Common Thermoplastics to Use for Injection Molding

Posted: January 4, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Types,

Small Plastic Parts,

Glass-Filled Nylon

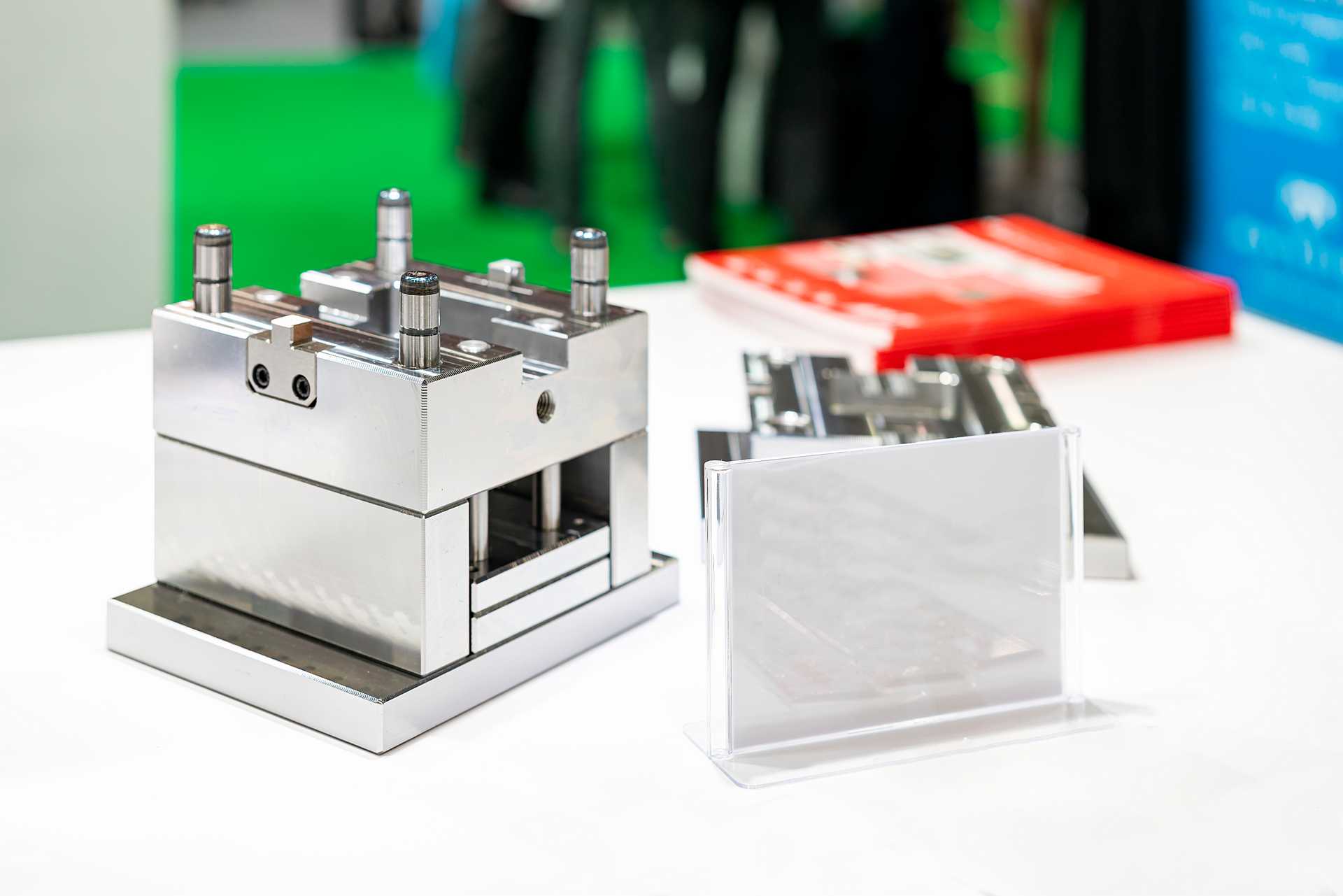

Injection Molding 101: Plastic Injection Molding and Thermoplastics

Posted: December 9, 2021 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Injection Molding Tooling,

Choosing the right plastic injection molder

Thermoplastic injection molding is a common process used for the mass production of parts by using specialized machines. The technique works by injecting molten thermoplastic resin into a mold under high pressure, where it is held until cooled into solid form. If you have ever been curious to learn more about this important process, then you are in luck! Read through this guide and discover what is possible with thermoplastic injection molding.

A Beginner’s Guide To Plastic Injection Molding

Posted: November 30, 2021 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Injection Molding Tooling,

Choosing the right plastic injection molder

10 Most Popular Uses of Outdoor Electrical Enclosures

Posted: November 16, 2021 by

Jon Gelston

Tags:

plastic enclosures,

Outdoor enclosures

Our experienced team continually serves our customers, producing plastic parts for a variety of needs. One particular type of product, outdoor electrical enclosures, is commonly used across countless industries. Explore the ways that AIM Processing can meet all of your outdoor electrical enclosure needs, all of which are manufactured according to ISO 9001:2015 standards.

Subscribe to Email Updates

Posts by Topic

- Quality (59)

- Choosing the right plastic injection molder (47)

- Plastic Types (46)

- Plastic Injection Molding (44)

- Plastic Injection Molding Defects (41)

- Texture (30)

- Small Plastic Parts (25)

- Plastic vs. metal (21)

- Electronic Enclosures (15)

- Plastic Injection Molding Tooling (14)

- Waterproofing (13)

- plastic enclosures (11)

- Outdoor enclosures (8)

- Plastic Gate Design (6)

- insert molding (6)

- vacuum forming (4)

- Assemblies (3)

- Nylon Injection Molding (3)

- elastomeric overmolding (3)

- Customer (1)

- Glass-Filled Nylon (1)

- Insert Molding vs. Overmolding (1)

- Lettering and Logos (1)

- News (1)

- Tool Transfer (1)

- Tradeshow and Events (1)

- injection molding (1)

- laser engraving (1)

- laser etching (1)

- plastic injection molding Colorado (1)

SINCE 1993 MADE IN USA

SINCE 1993 MADE IN USA