Plastic injection molding services are increasingly crucial within today’s medical and tech sectors. From state-of-the-art medical devices and specialized healthcare equipment to complex electronics components and everyday gadgets, molded plastic products can be found in virtually every facet of modern day life.

Of course, medicine, healthcare, electronics manufacturing, and the various tech industries are some of the fastest growing markets in Colorado and across the nation. More and more vendors in these niches are demanding the highest quality American injection molding companies to manufacture their products lean, reliably, and as sustainably as possible – all while simplifying their supply chains. Enter AIM Processing, one of the greater Colorado region’s leading injection molding service providers.

Jon Gelston

Recent Posts

The Role of AIM Processing in Colorado's Medical and Tech Industries

Posted: August 23, 2023 by

Jon Gelston

Tags:

Plastic Injection Molding Defects,

Plastic Types,

Quality,

Plastic vs. metal,

Texture,

Small Plastic Parts,

Choosing the right plastic injection molder,

Nylon Injection Molding

Plastic Injection Molding with Nylon: Material Strengths and Applications

Posted: August 10, 2023 by

Jon Gelston

Tags:

Plastic Injection Molding Defects,

Plastic Types,

Quality,

Plastic vs. metal,

Texture,

Small Plastic Parts,

Choosing the right plastic injection molder,

Nylon Injection Molding

Nylon is a highly versatile thermoplastic material that is used in many specific injection molding applications today. An extremely durable and chemically-resistant plastic, nylon is commonly used in automotive electronic connectors, protective casings, enclosures, metal replacement parts, and high-wear mechanical components.

Common Injection Molded Plastic Materials Compared

Posted: July 27, 2023 by

Jon Gelston

Tags:

Plastic Injection Molding Defects,

Plastic Types,

Quality,

Plastic vs. metal,

Texture,

Small Plastic Parts,

Choosing the right plastic injection molder,

vacuum forming

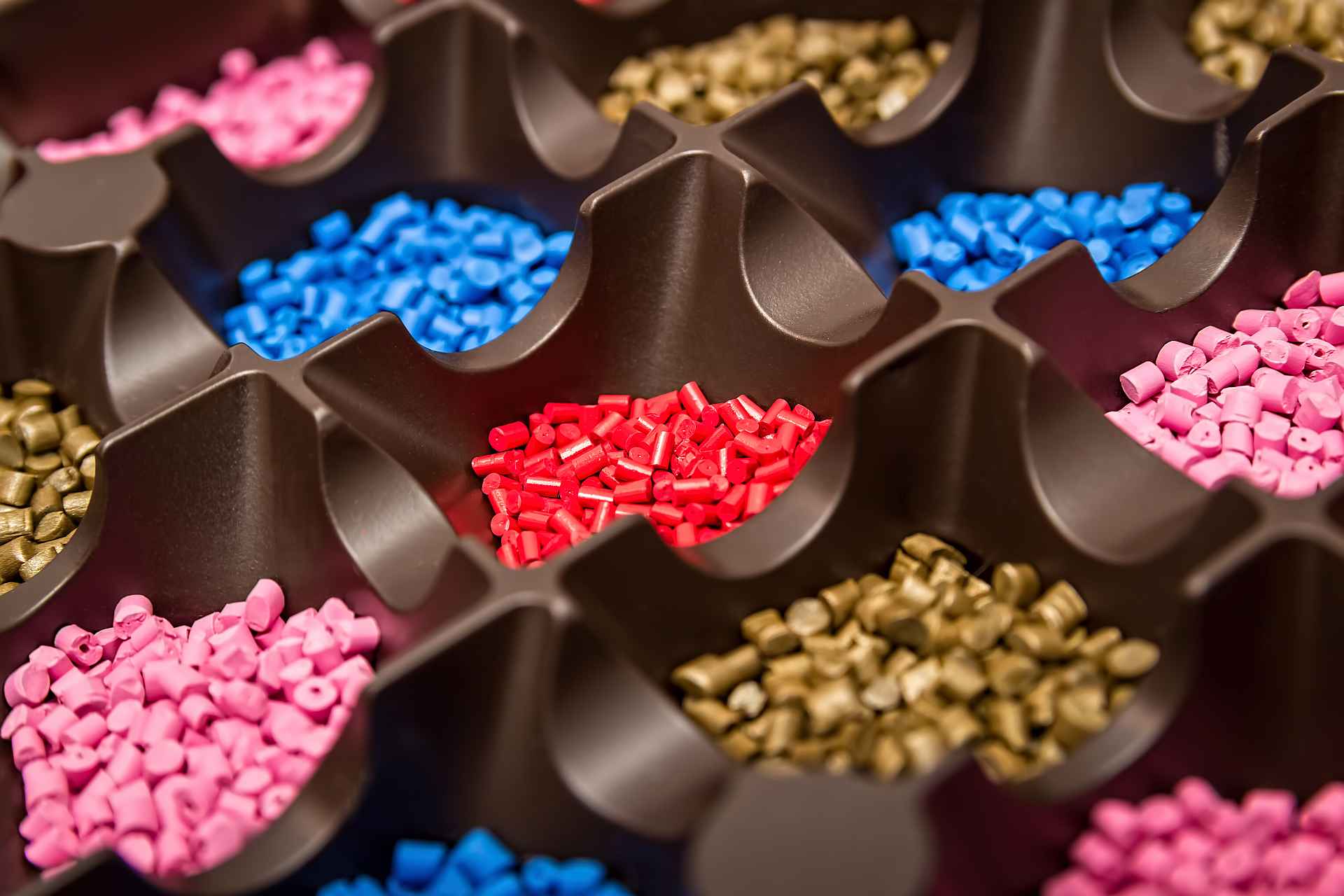

There are many different common types of plastics used in the injection molding industry today. And for many projects, there will be numerous suitable plastics to choose from.

Of course, choosing the best thermoplastic material for your project isn’t simply a case of going with the strongest and most durable option, or choosing the cheapest suitable material. You have to carefully consider the use cases for your end products, all of the performance requirements, potential reliability issues that may arise, as well as the overall material cost, availability, and sustainability.

Injection Molding vs. Compression Molding: Advantages and Applications (Clone)

Posted: July 26, 2023 by

Jon Gelston

Tags:

Plastic Injection Molding Defects,

Plastic Types,

Quality,

Plastic vs. metal,

Texture,

Small Plastic Parts,

Choosing the right plastic injection molder,

vacuum forming

The Benefits of Plastic Injection Molding Compared to Extrusion

Posted: June 29, 2023 by

Jon Gelston

Tags:

Plastic Injection Molding Defects,

Plastic Types,

Quality,

Plastic vs. metal,

Texture,

Small Plastic Parts,

Choosing the right plastic injection molder,

vacuum forming

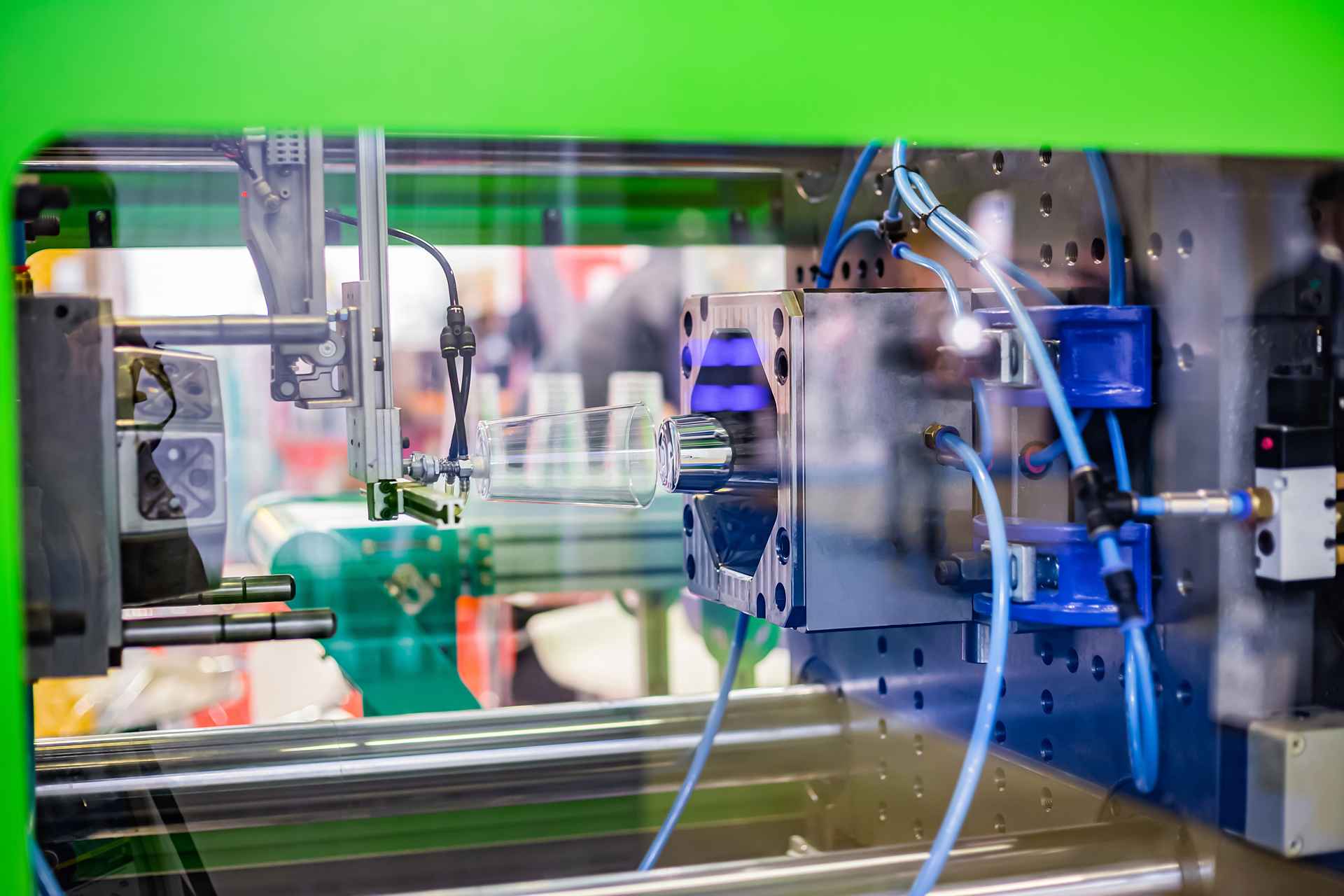

Plastic injection molding is sometimes compared to extrusion when customers are searching for the most optimized manufacturing method for their products. While the injection molding and extrusion processes are very different, they are both capable of producing high-quality parts with complex designs.

Nevertheless, there are certain types of products – or production goals – which are much better suited for the injection molding process, and vice versa. Learn more about these two unique manufacturing services below, including the common advantages and product applications.

The Advantages of Plastic Injection Molding vs. Vacuum Forming

Posted: June 15, 2023 by

Jon Gelston

Tags:

Plastic Injection Molding Defects,

Plastic Types,

Quality,

Plastic vs. metal,

Texture,

Small Plastic Parts,

Choosing the right plastic injection molder,

vacuum forming

While injection molding services are often compared or even cross-shopped with vacuum forming, which is a specialized form of thermoforming. However, the two manufacturing processes are actually quite different, and each is uniquely optimized for different types of projects.

If you’d like to learn more about how the injection molding process works, check out our Brief Introduction to Injection Molding as well as our Plastic Injection Molding Services page. Or if you’d like to delve deeper into the advantages of injection molding specifically compared to vacuum forming, check out our comparison of the two processes below.Insert Molding vs. Overmolding: Two Custom Plastic Molding Processes Compared

Posted: June 1, 2023 by

Jon Gelston

Tags:

Insert Molding vs. Overmolding

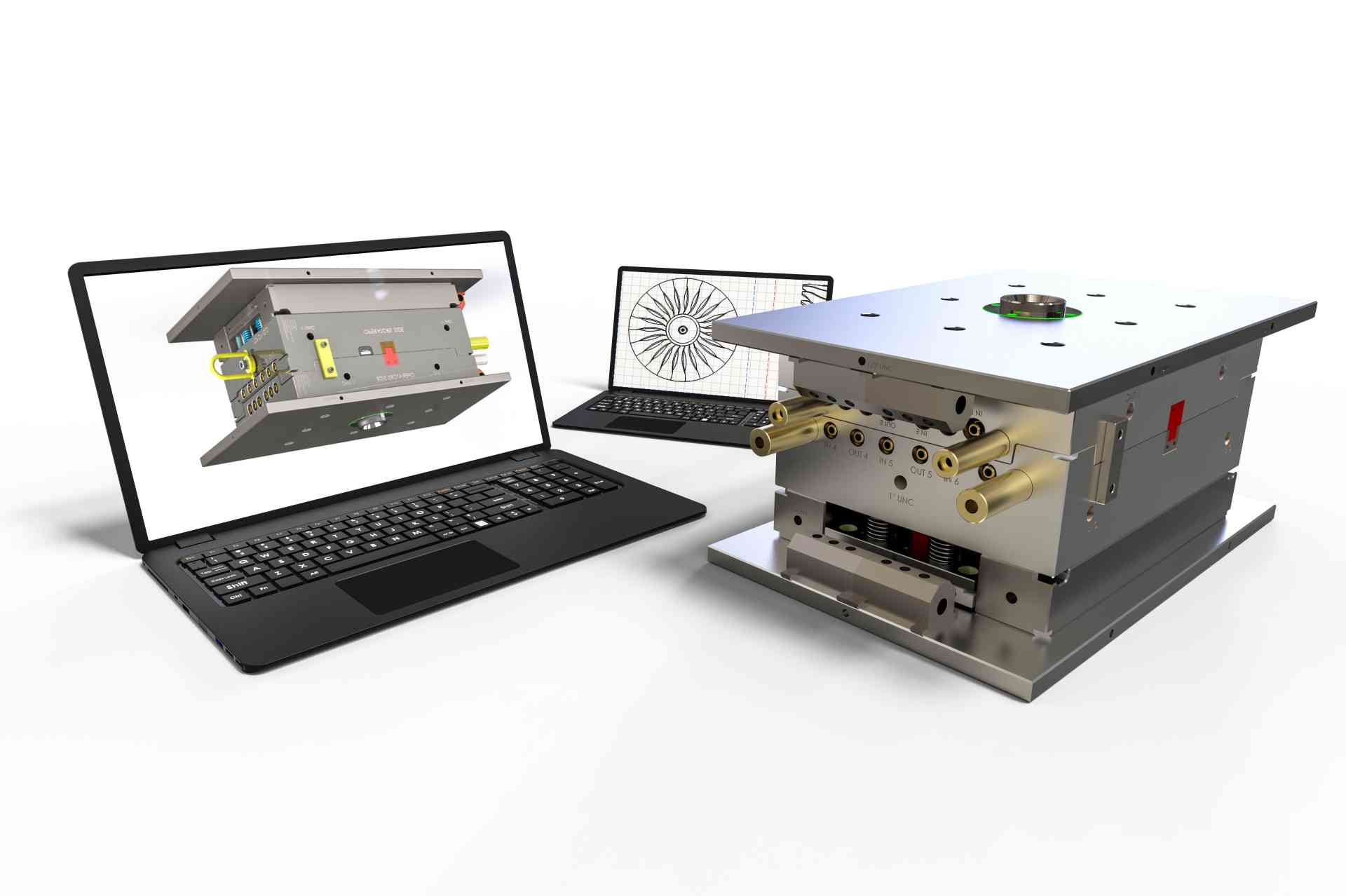

Two of the most common plastic injection molding services used throughout the industry today are insert molding and overmolding. These specialized production processes are so closely related that sometimes customers use the names interchangeably. However, there are some key technical differences which set these two crucial injection molding capabilities apart.

How Colorado Injection Molding Is Transforming the Industry

Posted: May 17, 2023 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Types,

Quality,

Small Plastic Parts,

Choosing the right plastic injection molder

For more than 50 years, the Colorado region has been a national hotspot for the injection molding industry. Throughout the decades, our state has served as one the nation’s primary bases in providing the custom toolmaking and injection molding services which are critical for manufacturing so many of today’s plastic products.

Injection Molding Companies in Colorado: The Benefits of Local Manufacturing

Posted: May 2, 2023 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Types,

Quality,

Small Plastic Parts,

Choosing the right plastic injection molder

The demand for quality American injection molding services continues to rise in 2023, with an increasing number of domestic sellers onshoring some or all of their plastic manufacturing operations. Colorado is no exception, continuing to evolve into a nexus for the state-of-the-art plastic molding industry.

Of course, reshoring is partly a response to international supply chain disruptions which have impacted higher level manufactured products over the last several years. Many customers are simply looking for a more reliable manufacturing partner that offers a more dependable supply chain. However, it’s also largely an embrace of the superior quality, convenience, and customer service that Colorado’s injection molding companies can offer.

Automation in Injection Molding: Making the US Globally Competitive

Posted: April 20, 2023 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Types,

Quality,

Small Plastic Parts,

Choosing the right plastic injection molder

Automated production technology has become increasingly common throughout the American manufacturing sector – and the plastic injection molding service industry is no exception. New automation technology allows domestic manufacturers to be substantially more efficient and more productive, and thus more cost-competitive with their overseas counterparts.

Subscribe to Email Updates

Posts by Topic

- Quality (59)

- Choosing the right plastic injection molder (47)

- Plastic Types (46)

- Plastic Injection Molding (44)

- Plastic Injection Molding Defects (41)

- Texture (30)

- Small Plastic Parts (25)

- Plastic vs. metal (21)

- Electronic Enclosures (15)

- Plastic Injection Molding Tooling (14)

- Waterproofing (13)

- plastic enclosures (11)

- Outdoor enclosures (8)

- Plastic Gate Design (6)

- insert molding (6)

- vacuum forming (4)

- Assemblies (3)

- Nylon Injection Molding (3)

- elastomeric overmolding (3)

- Customer (1)

- Glass-Filled Nylon (1)

- Insert Molding vs. Overmolding (1)

- Lettering and Logos (1)

- News (1)

- Tool Transfer (1)

- Tradeshow and Events (1)

- injection molding (1)

- laser engraving (1)

- laser etching (1)

- plastic injection molding Colorado (1)

SINCE 1993 MADE IN USA

SINCE 1993 MADE IN USA